2021 China New Design Composite Mount - 3K Laser cutting full carbon fiber sheet using in structural – Feimoshi

2021 China New Design Composite Mount - 3K Laser cutting full carbon fiber sheet using in structural – Feimoshi Detail:

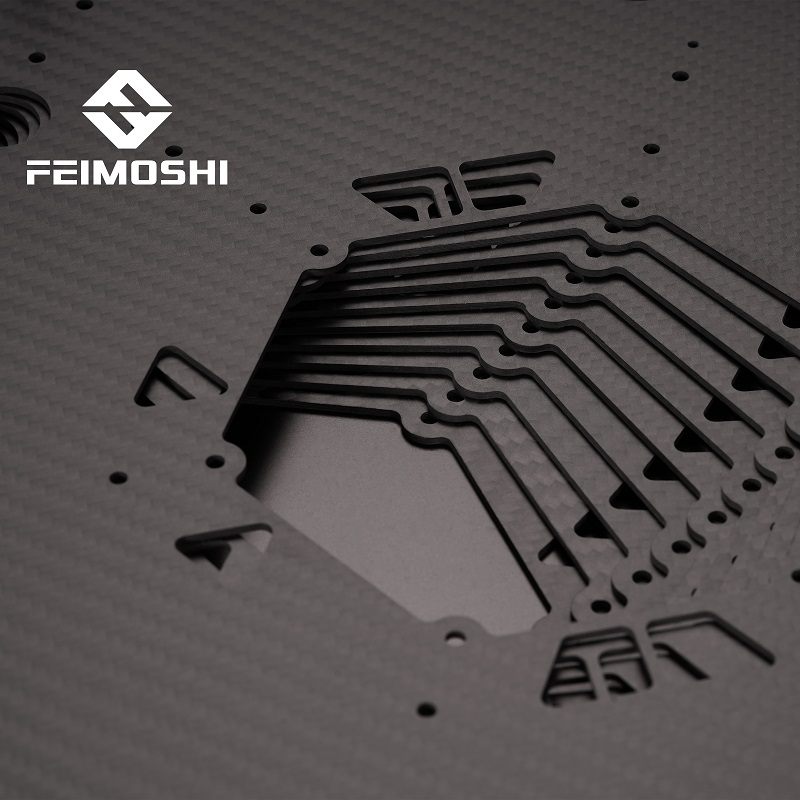

3K Laser cutting full carbon fiber sheet using in structural

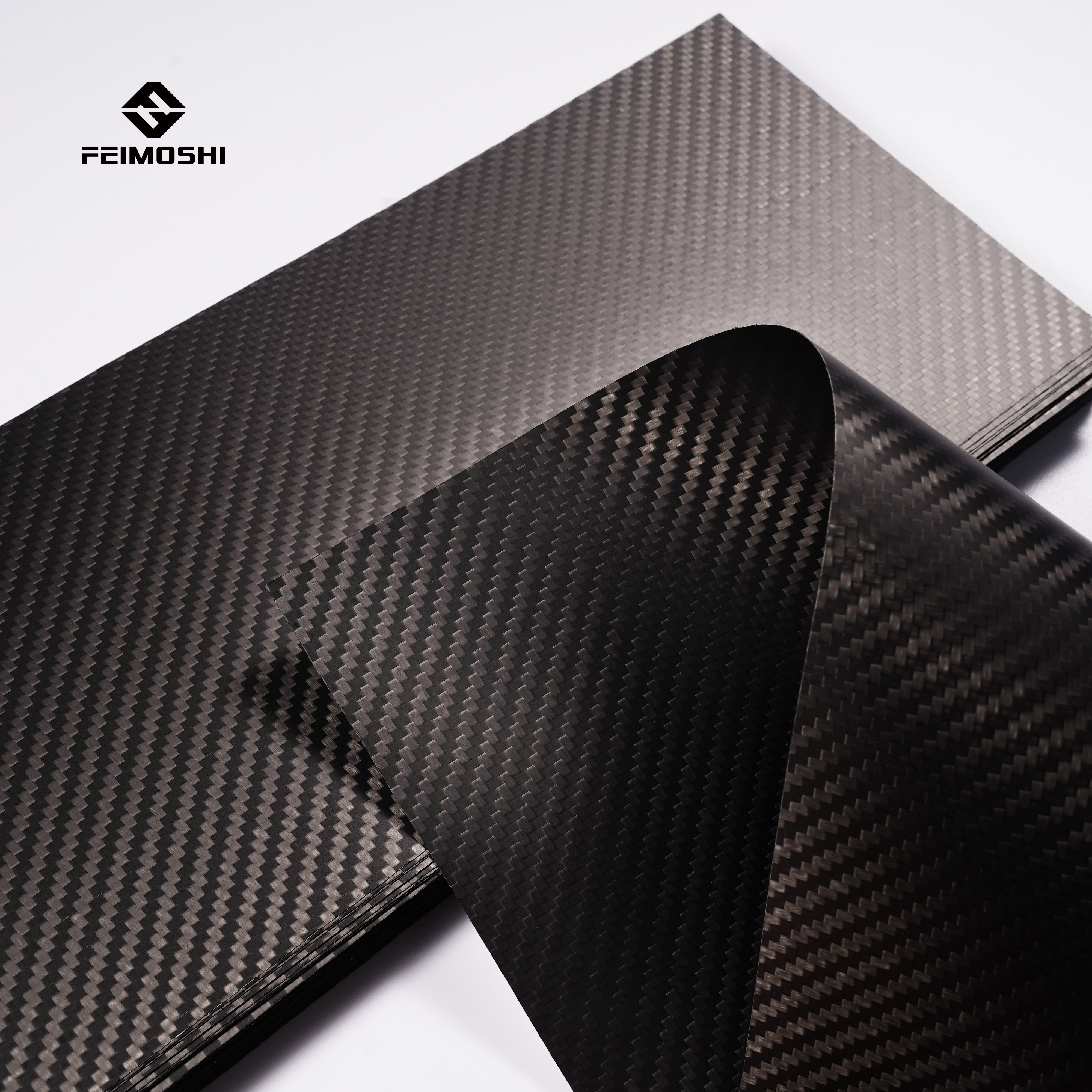

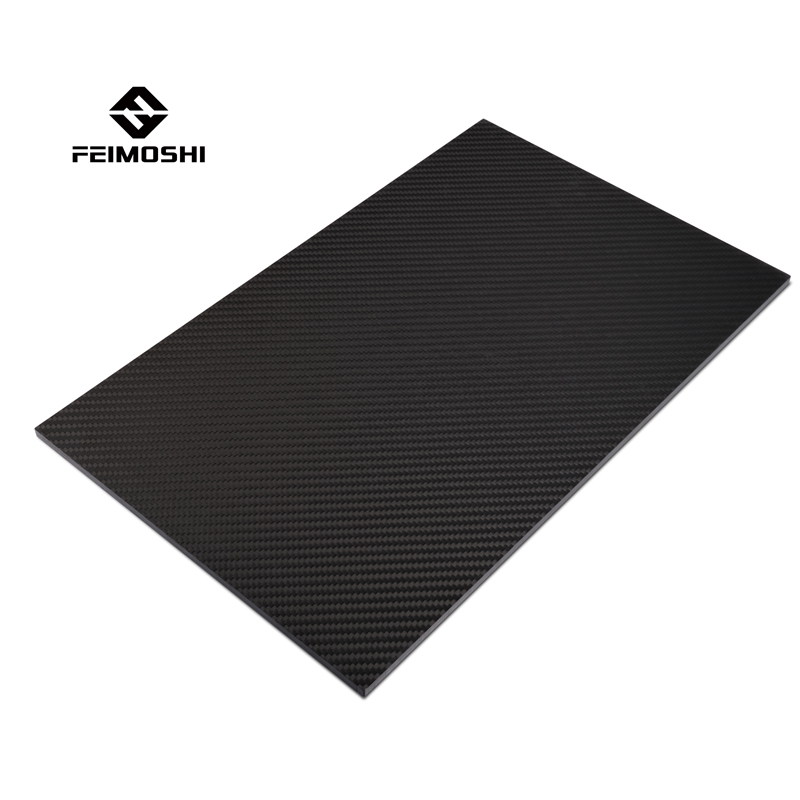

About the 3k twill matte Carbon Fiber Sheet,it is stronger and lighter.

Normally we have the thickness from 0.3mm to 30.0mm,especially we are strong in the field of CNC Carbon Fiber Cutting Service.

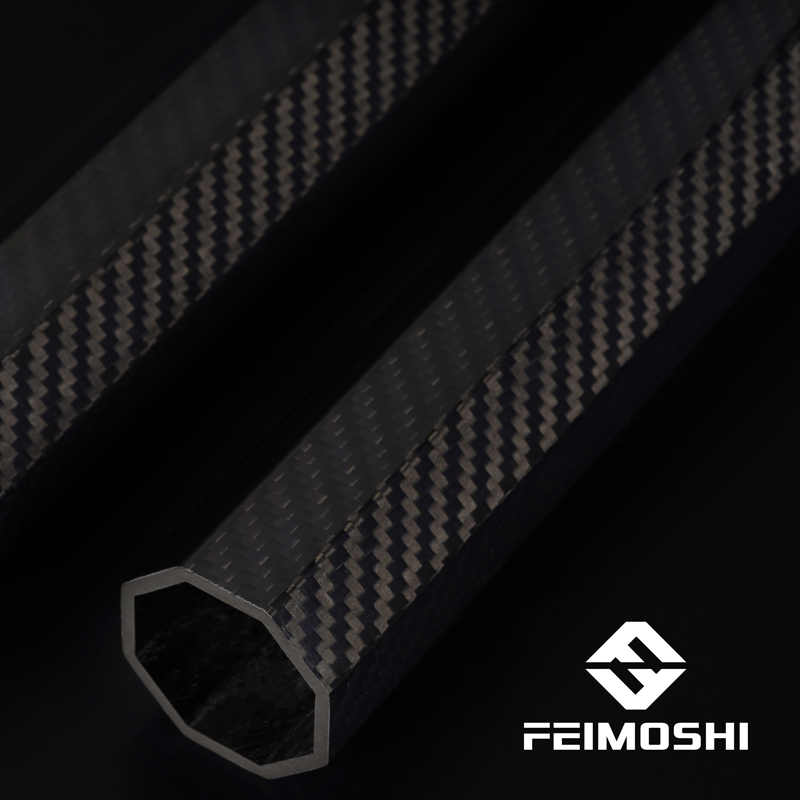

Our normal stock including full carbon fiber sheet(400X500mm, 500X600mm), carbon fiber round tube(Various OD and ID), carbon fiber octagon tube(20X30mm, 30X30mm), carbon fiber square tube(10X10mm, 18X18mm, 20X20mm, 25X25mm, 30X30mm), carbon fiber curved tube(22mm and 25mm).

CNC carbon fiber customized cutting is possible to process complex surfaces that are difficult to be machined by conventional methods, and can even process some unobservable parts.

FAQ

1) Could we order one set frame?

Yes, normally, we make the quotation according to the whole plate(400X500mm or 500X600mm). It will be more competieve price based on the quantity in whole plate.

2)Do you do the carbon fiber chamfer and carbon fiber countersunk?

Yes, we have many years experience for the chamfer and countersunk.(DXF, DWG, Step format)

3)Could you do the forged plate?

Yes, forged plate is the new material. We would like to try to offer the perfect plates.

4)Do you help us to check the drawing’s hole size?

Yes, our engineer will check the drawings when cutting.

5)How many days for the cutting and plate?

Normally, it needs about 7-15 working days to complete it. Also we have to promise the quality 100%.

Looking for ideal 3.0mm Carbon Fiber Sheet Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the 4.5mm Carbon Fiber Sheet are quality guaranteed. We are China Origin Factory of 5.0mm Carbon Fiber Sheet. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber greatly improves the characteristics of special-shaped parts. At this stage, carbon fiber special-shaped products have many requirements in the fields of unmanned aircraft, auto parts, intelligent robots, etc. 2021 China New Design Composite Mount - 3K Laser cutting full carbon fiber sheet using in structural – Feimoshi , The product will supply to all over the world, such as: Romania, Stuttgart, Romania, Disadvantages of carbon fiber frames: (1) Complicated internal stress calculation; carbon fiber frame is composed of carbon fiber, which is characterized by strong tensile strength, but weak breaking compressive strength. Rigidity), the carbon fiber sheet is re-formed according to the calculation. The production and processing technology varies from manufacturer to manufacturer. It is important to select products from reliable manufacturers with work experience.(2). It is difficult to change the specifications; it is difficult to change the specifications because the molds are formed after forming. There is no way to correspond to order information of multiple specifications and styles.(3). Aging; will the application of epoxy resin cause aging? This is a study of the subject of beings, and it will slowly turn white when placed under the sun. Naturally this situation is related to the technicality of the manufacturer. Try not to place it in the sun.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.