OEM/ODM Manufacturer Carbon Fiber Structural Component - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi

OEM/ODM Manufacturer Carbon Fiber Structural Component - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi Detail:

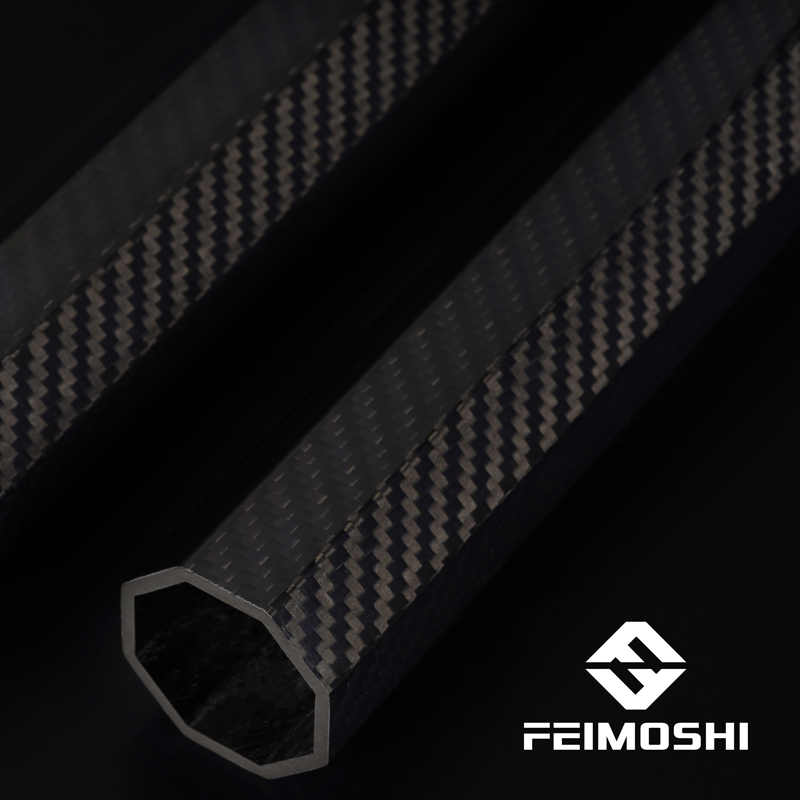

Customized carbon fiber octagonal tube accessories

New upgrading Octagon carbon fiber boom types in stock: 20X30mm, 30X30mm(Length is 1000mm.) We could cut the different length according to your detail requirements( Free cut length charge)

Thicknesss could do the 1.0mm, 1.5mm and 2.0mm or others. Octagon carbon fiber tube is more stable and professional than round carbon fiber tube.

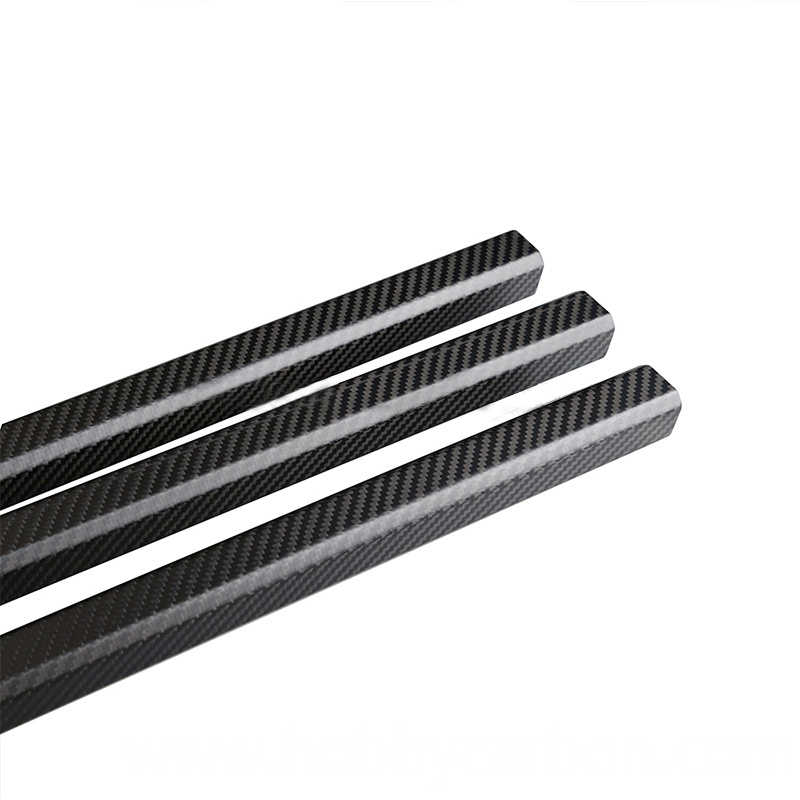

These 3K Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill or plain weave;

Customized specs are accepted, like Outer Diameter : 6mm, 8mm,10mm,12mm,14mm,16mm, 20mm, 22mm, 25mm, 30mm……350mm;

Thickness:

1mm, 1.5mm, 2 mm, 2.5mm, 3mm…..16mm ;any size can do for you .

2.Specifications

1) High temperature resistance carbon fiber tubes:100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

Besides Carbon Fiber Tube, we also can support you with Full Carbon Fiber Sheet, shaped carbon fiber parts, carbon fiber prototyping, carbon fiber guitar, carbon fiber rc chassis and carbon fiber furniture and so on.

We have about ten years more experience in carbon fiber market. Assembly serivce and packing service is welcomed by most customers. Any other requirements, please don’t hesitate to contact us.

Welcome to quote

Specification in common use

|

23mm*25mm*1000mm |

20mm*22mm*1000mm |

|

19.5mm*22mm*1000mm |

18mm*20mm*1000mm |

|

18mm*16mm*1000mm |

14mm*16mm*1000mm |

|

10mm*12mm*1000mm |

8mm*10mm*1000mm |

|

6mm*8mm*1000mm |

can custom as per customer’s requires |

FAQ

1) Do we need to make a mould for the shaped carbon fiber tube?

Yes, most of carbon fiber tube needs a mould to do it. And it will make the tube more straight and strength.

2) There is the moq requirements of shaped carbon fiber tube?

If you make the new mould for your project, the testing order is no moq for you.

3)When we decide to make the mould, it needs to make the payment for each order?

No, mould charge only need to pay one time. Ant the mould is only for you.

4) Could we sign the NDA?

Yes, it is ok for us. And it is also our duty to protect every customer’s design.

Looking for ideal Carbon Fiber Arms Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the X Class Frame are quality guaranteed. We are China Origin Factory of Big Carbon Fiber Drone. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. OEM/ODM Manufacturer Carbon Fiber Structural Component - 30x20mm custom carbon fiber octagonal square tube accessories – Feimoshi , The product will supply to all over the world, such as: Bulgaria, Sydney, Johannesburg, The characteristics of carbon fiber tube:1. High tensile strength: The strength of carbon fiber is 6-12 times that of steel, which can reach more than 3000mpa.2. Low density and light weight. The density is only less than 1/4 of steel.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!