PriceList for Carbon Fiber Profile - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi

PriceList for Carbon Fiber Profile - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi Detail:

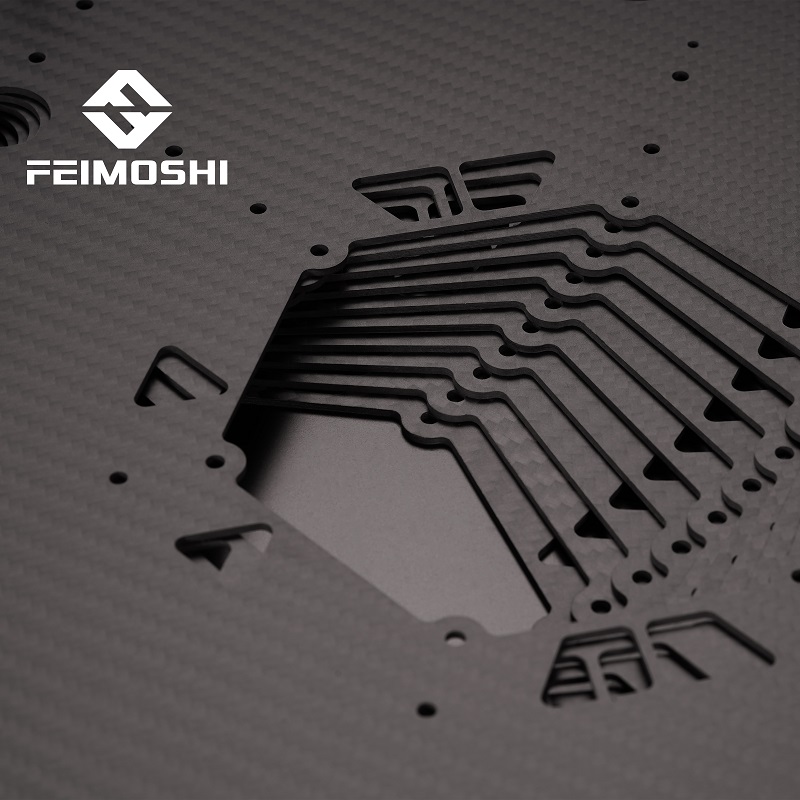

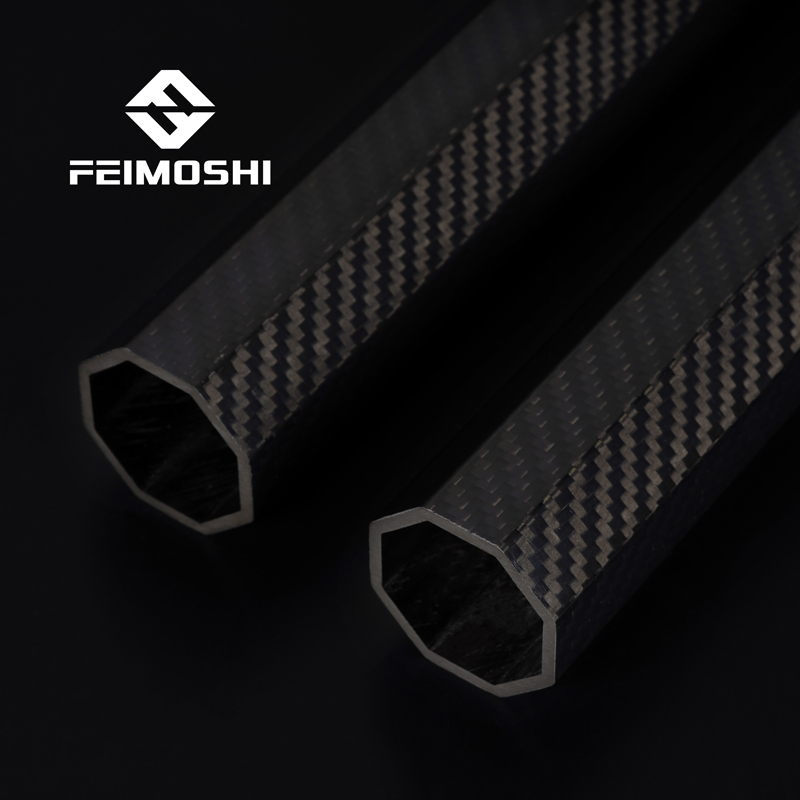

DIY 3K large diameter Carbon fiber round/square rod boom

Product Description

Our Carbon Fiber Tube is great performance and appearance. Made from attractive pattern plain twill or as customer requirement.

We make the Carbon Fiber Tubes by rolling-Wrapped process. It makes the carbon fiber tube much stronger and professional. More and more customers choose the full carbon fiber tube to make the drone arm, desk leg, gimbal stand and so on. And you could offer your creative ideal, we could help you to come ture. Carbon fiber tube is also widly used in building construction. It makes them much lighter and easy to move.

Material: 100% carbon fiber, Vinyl resin, Epoxy resin.

Thickness:1.0mm/1.5mm/2.0mm

Length: longest length is 2000mm

Appearance: 3K twill weave, plain weave, or other

Looking for ideal Carbon Fiber carbon fiber tube Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Epoxy Resin Carbon Fiber 3k Woven are quality guaranteed. We are China Origin Factory of Carbon Fiber Shape. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. PriceList for Carbon Fiber Profile - DIY 3K large diameter Carbon fiber round/square rod boom – Feimoshi , The product will supply to all over the world, such as: Gabon, New Zealand, Uganda, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

A good manufacturers, we have cooperated twice, good quality and good service attitude.