Special Design for Rc Carbon Fiber Frame - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi

Special Design for Rc Carbon Fiber Frame - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi Detail:

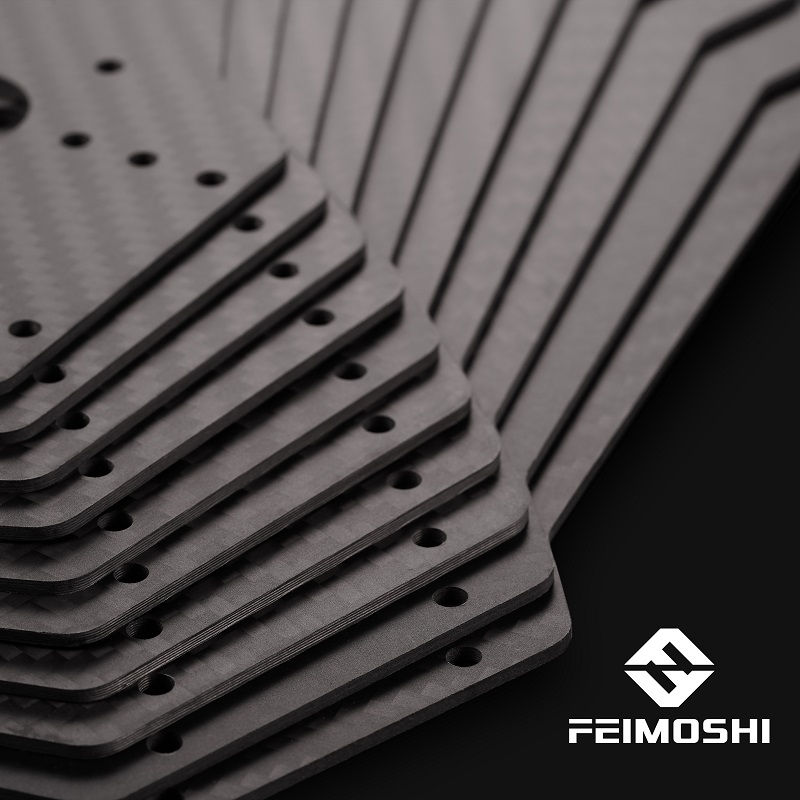

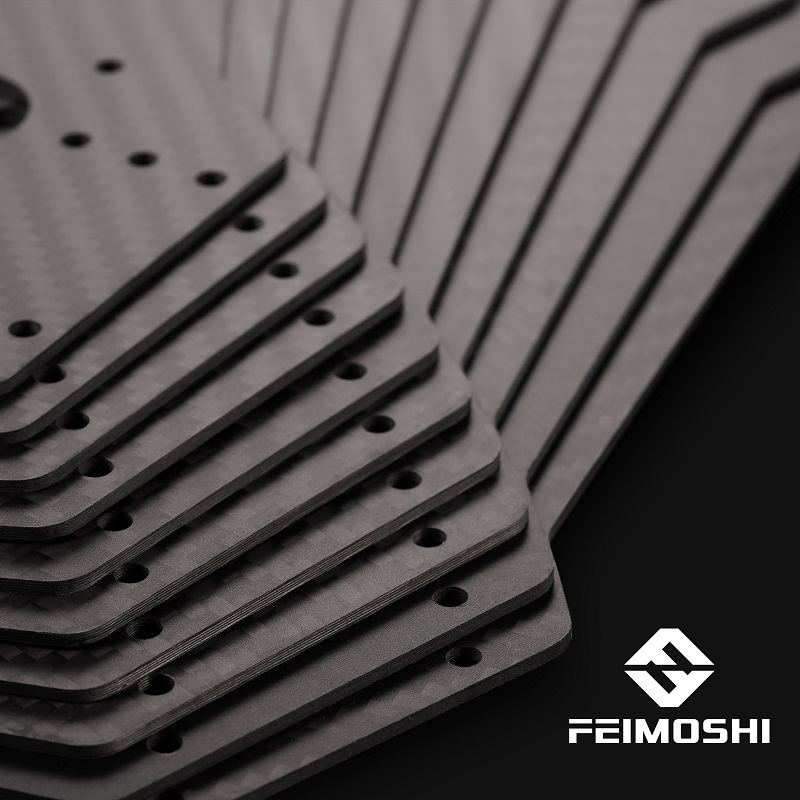

3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels

Carbon fiber plates are made from high-quality carbon fiber material, our carbon fiber sheets panels are durable, high quality, and affordable.

1. All our carbon fiber sheets are made with 100% real carbon fiber prepreg cloth. Varieties of carbon fiber sheets can be offered to meet different requirements.

2. Each sheet is hand finished and inspected. Special materials and processes ensure the flawless gloss on both sides.

3. Different thicknesses and sizes for choosing :

Size :400×500 ;500×500; 500x600mm thickness :0.3-20mm

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for testing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing.

Product detail pictures:

Related Product Guide:

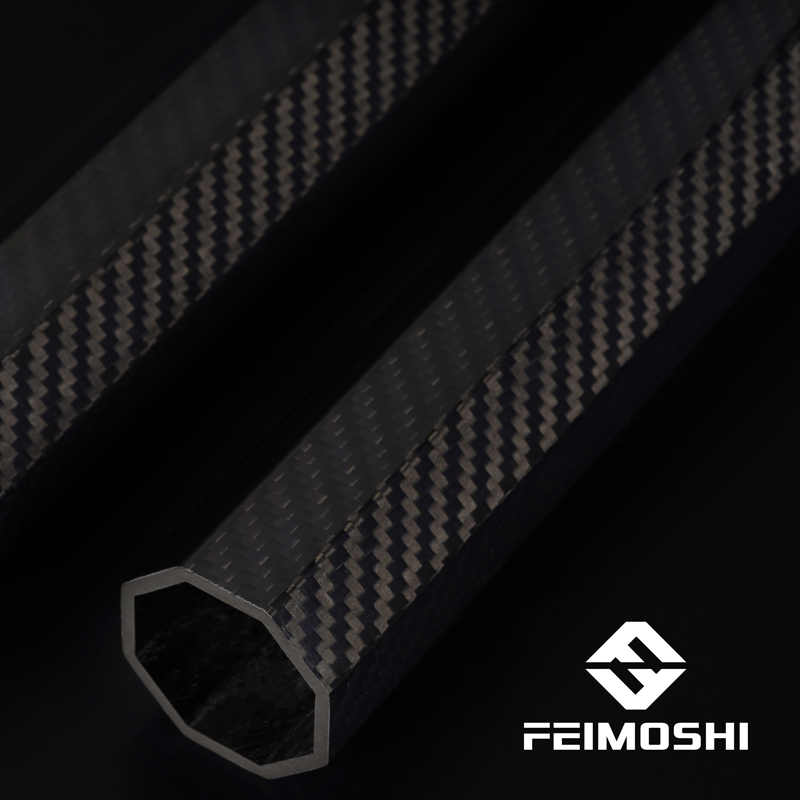

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Special Design for Rc Carbon Fiber Frame - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi , The product will supply to all over the world, such as: Jakarta, Curacao, The Swiss, Carbon fiber board mainly has the following characteristics:1. Light weight and high toughness. The weight of carbon fiber board is similar to that of plastic of the same volume, which is 20% of that of steel. Although it is light, its toughness is comparable to that of steel. It can be bent and coiled.2. High tensile coefficient. The tensile coefficient of carbon fiber is several times higher than that of steel, and it has good resistance to deformation, so carbon fiber boards are used in concrete reinforcement, bridge reinforcement and other places.3. Good chemical stability. Carbon fiber board base material is carbon element, carbon element has good chemical stability, and has the characteristics of corrosion resistance, acid and alkali resistance, wear resistance and so on.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.