Special Design for Rc Carbon Fiber Frame - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi

Special Design for Rc Carbon Fiber Frame - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi Detail:

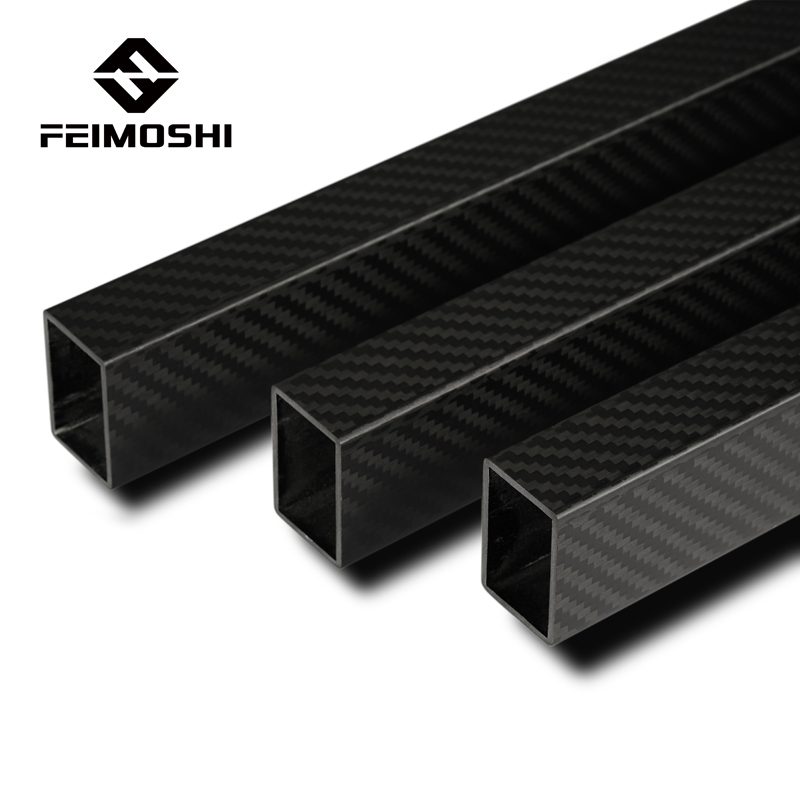

Custom Octagonal composite carbon fiber square tube for accessories

In these recent years, custom carbon fiber tube is more populare in the drone market.

Also we have carbon fiber round tube, carbon fiber octagonal tube and carbon fiber square tube in stock.

Different size and type is avaliable for your choosing.

Small carbon fiber round tube could be inserting the large carbon fiber tube according to your requirements.

Carbon fiber rectangle tube, large carbon fiber tubes, carbon fiber tube handguard, ect. are all customized according to your requirements.

If you have any other requirements, please don’t hesitate to contact us.

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Special Design for Rc Carbon Fiber Frame - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi , The product will supply to all over the world, such as: Jersey, Puerto Rico, Greenland, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

Send your message to us:

Write your message here and send it to us