Best quality Custom Carbon Fiber Tubes - 3K Full Carbon Fiber round Tubes desgin – Feimoshi

Best quality Custom Carbon Fiber Tubes - 3K Full Carbon Fiber round Tubes desgin – Feimoshi Detail:

3K Full Carbon Fiber Tubes and Connectors

Carbon Fiber Tube has been widely used in hitech fields, such as aerospace, modern sewing machinery, petrochemical industry, medical machinery, automobiles, machinery manufacturing, construction, sports and entertainment items, telecommunication, electrical heating etc.

Carbon fiber roll wrapped tubes are ideal for all kinds of construction projects that require a light weight high performance sporting tube that can deal with forces from any direction.

Any intersting in pls feel free let us know.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal 3K Full Carbon Tubes Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Booms are quality guaranteed. We are China Origin Factory of Carbon Tubes and Connectors. If you have any question, please feel free to contact us.

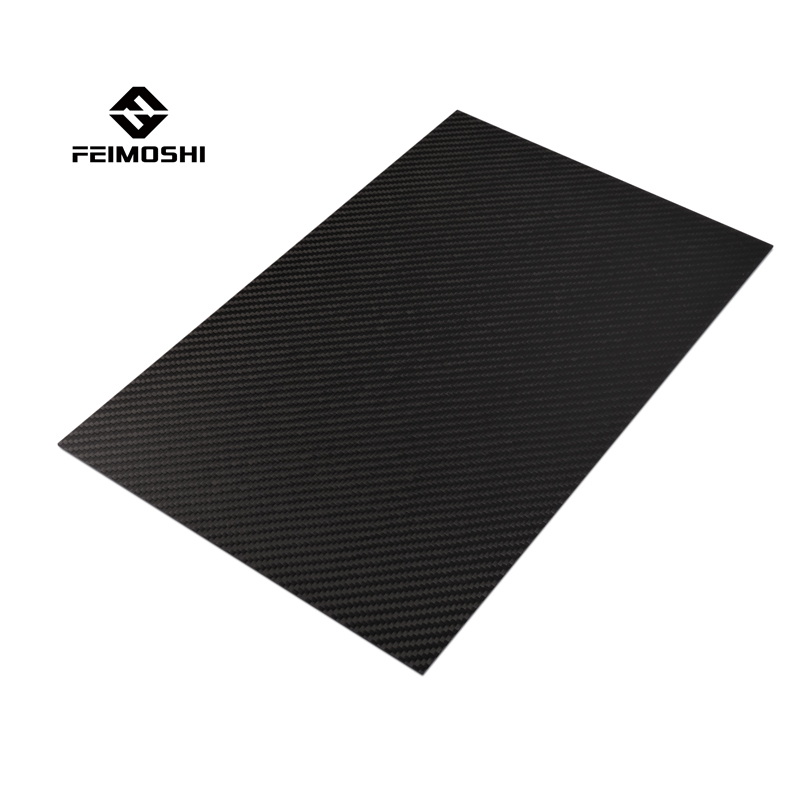

Product detail pictures:

Related Product Guide:

2. Low thermal expansion coefficient. A low coefficient of expansion is beneficial for improving the accuracy of the company's products. Best quality Custom Carbon Fiber Tubes - 3K Full Carbon Fiber round Tubes desgin – Feimoshi , The product will supply to all over the world, such as: Nepal, Surabaya, Mexico, In general, grinding and filing can grind the edges of sharp carbon fiber boards to a smooth appearance. However, if the fiberboard is exposed to harsh environments for a long time, such as marine environments, a two-part epoxy laminate is used to seal the edges.According to the different divisions of carbon fiber precursors, there are generally pitch-based carbon fiber cloth, PAN-based carbon fiber cloth, and viscose-based carbon fiber cloth.Second, according to different specifications, it can be divided into 1K, 3K, 6K, 12K and 24K and above carbon fiber cloth.Third, according to different carbonization, it can also be divided into graphitized carbon fiber cloth, (this carbon fiber cloth can withstand high temperature of 2,000 to 3,000), carbon fiber cloth (can cope with high temperature of about 1,000 degrees), and pre-oxidized carbon fiber cloth (can Resist the high temperature of 200~3 Baidu).Fourth, according to different manufacturing methods, subsequent divisions can be performed. Woven carbon fiber cloth, generally two-dimensional cloth, three-dimensional cloth and three-dimensional woven cloth, etc.; carbon fiber prepreg cloth, including dry and wet prepreg cloth; carbon fiber non-woven fabric, non-woven fabric, also known as chopped strand mat, Continuous felt, surface felt, stitched felt, etc.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.