Factory Cheap Hot Curved Carbon Fiber Tube - high quality 3k full carbon fiber round tube – Feimoshi

Factory Cheap Hot Curved Carbon Fiber Tube - high quality 3k full carbon fiber round tube – Feimoshi Detail:

Product Description

Carbon fiber tube is composed of Carbon Fiber Twill (or Plain) Weave Fabric, Unidirectional Carbon

Fiber prepreg and epoxy resin. The tube is firstly table rolled with a mandrel of certain diameter and length.

Then put into the oven of high temperature for thermoset process. To reach high precision,

the tubes are usually ground and then put onto the epoxy spray if Glossy shinny finish needed.

Surface Finish: Glossy and Matte

Application: Aviation, models, vehicle modification and metal machine parts processing.

The main size and specifications: Fiber Specifications:1K,3K

Weaving Style: Plain. Twill

Fiber Type: Carbon fiber+carbon fiber, Carbon fiber+ glass fiber, Carbon fiber+aramid fiber

Thickness: Specific thickness can be met according to customer needs)

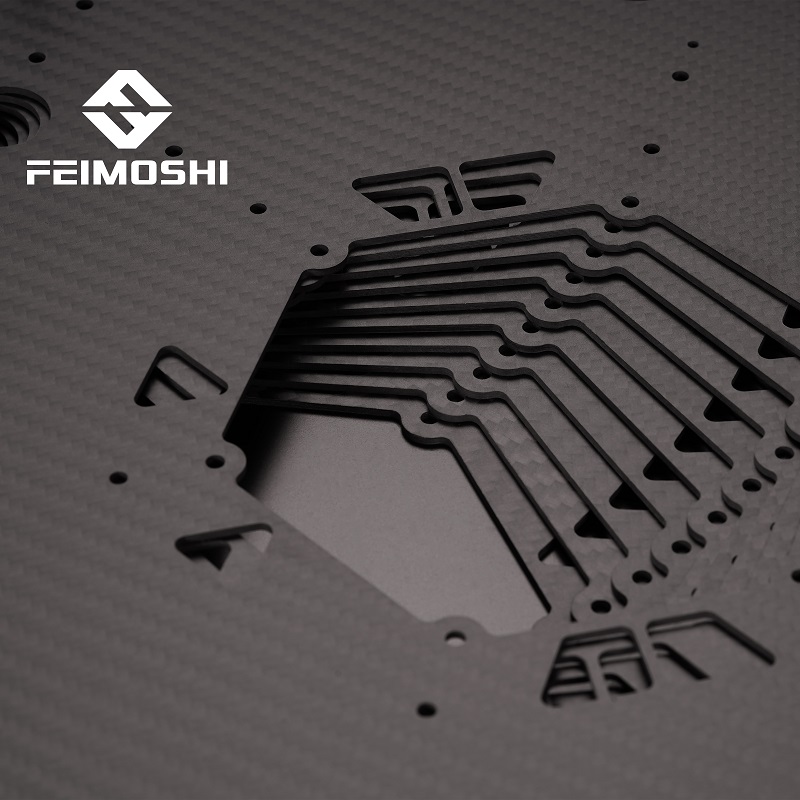

Service:CNC Customized Hardware.Logo service.CNC Cutting Service And Logo Printing

Product detail pictures:

Related Product Guide:

In the aerospace industry, carbon fiber sheets are used to make aircraft components such as fuselage panels, control surfaces and wingtips. The resulting components are lightweight, yet robust. Carbon fiber is widely adopted by the aerospace industry due to its superior strength-to-weight ratio. Because carbon fiber has such a beautiful appearance, it is also ideal for aircraft interiors. Factory Cheap Hot Curved Carbon Fiber Tube - high quality 3k full carbon fiber round tube – Feimoshi , The product will supply to all over the world, such as: Holland, Canberra, Ghana, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.