Factory Cheap Hot Drill Composite Boom - 3K carbon fiber CNC cutting parts – Feimoshi

Factory Cheap Hot Drill Composite Boom - 3K carbon fiber CNC cutting parts – Feimoshi Detail:

3K Carbon Fiber CNC Cutting parts

Have you designed your own frame and are looking to have it cut?

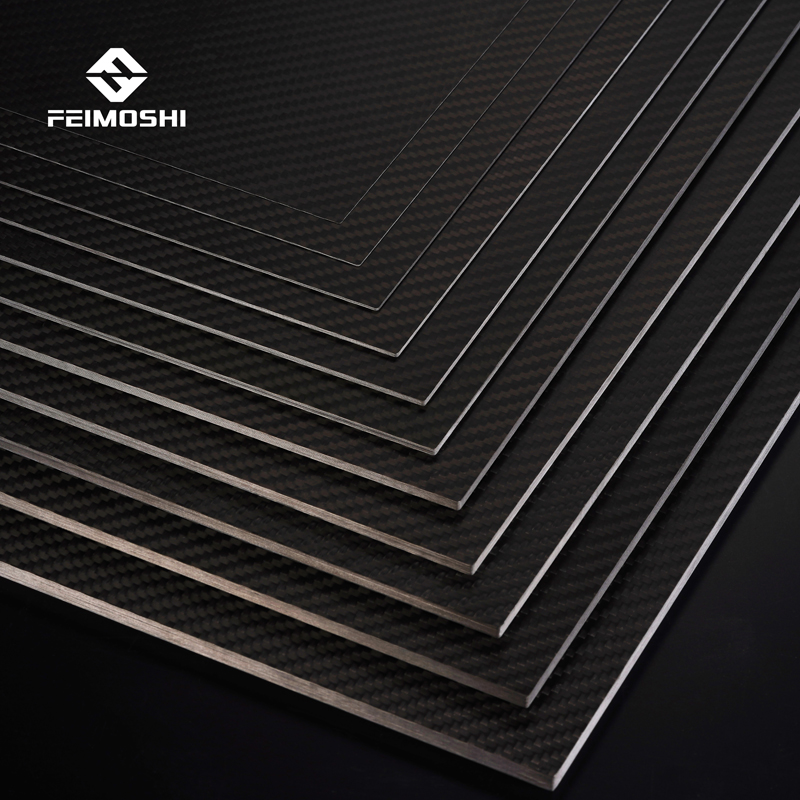

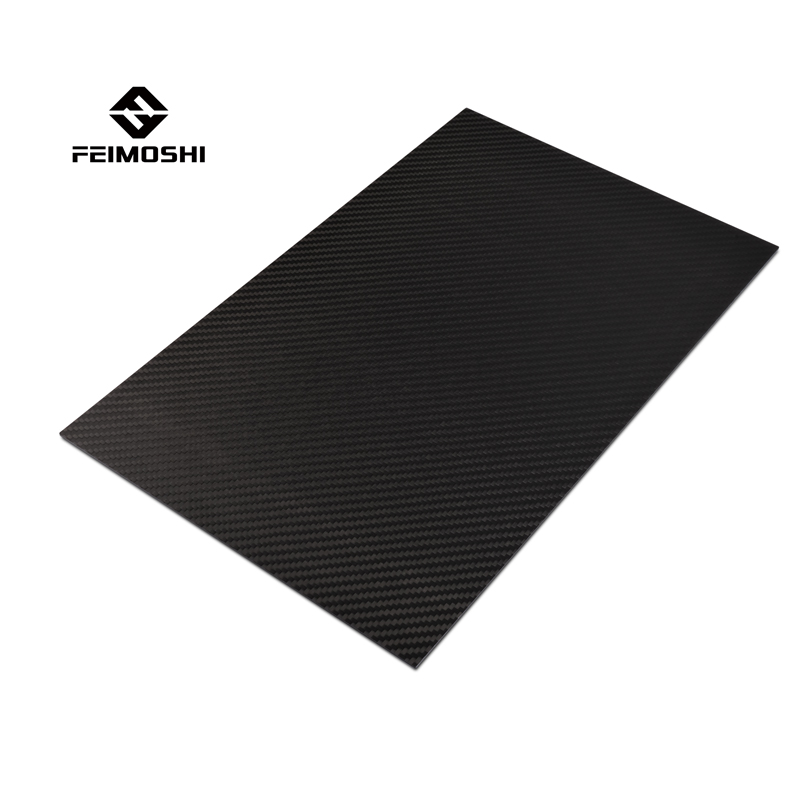

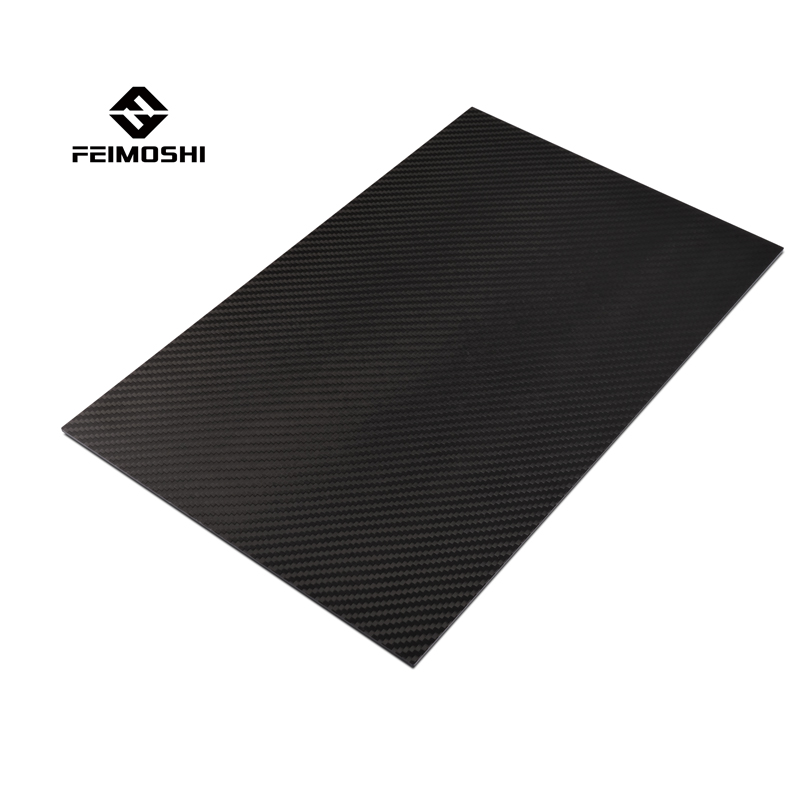

We can turn it into a reality for you. We carry high quality 3K Twill, Matte Finish Carbon Fiber Plates in .5, 1, 1.5, 2, 2.5, 3, 4 & 5mm thickness (up to 500 X 600mm). We can also special order other sizes and types of finishes. All Carbon Fiber edges are lightly wet sanded to clean them up after cutting.

We support CNC Carbon Fiber Cutting, shaped carbon fiber part, customized carbon fiber tube( curved carbon fiber tube, Octagon carbon fiber boom) and Logo Service.

Material: full carbon fiber plates sheets

Size: 400x500mm, 500X600mm, 600X800mm, 800X1000mm or other customized size

Surface: 3K/1K twill/Plain matt/Glossy

Stock: twill matte 0.5-10.0mm full carbon plates in stock

Service: OEM & ODM and CNC cutting services

Our service

* Drawings, photos and samples are welcome.

* We can produce the products as to your requirement or samples. Special for your own.

* Please contact us freely if there is any question.

* We are looking forward to have a good cooperation with you.

* Welcome to Hobby Carbon!

FAQ

Q:1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q: 2. What is the lead time?

A:Sample needs 1-3 days, mass production needs 10-15 days, also according to the order volume.

Q: 3. Do you have any MOQ limit?

A: Our MOQ is 200pcs for both formal raw material and processing parts.

Q: 4. Can you accept mixed batch of different products?

A: Yes, we are support different product mix wholesale, no limit of raw materials and mechanical parts, and color specifications, etc

Q: 5. How do you ship the goods and how long does it take arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

Looking for ideal Carbon 3K Fiber Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the CNC Cutting Parts are quality guaranteed. We are China Origin Factory of Carbon Fiber CNC. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Factory Cheap Hot Drill Composite Boom - 3K carbon fiber CNC cutting parts – Feimoshi , The product will supply to all over the world, such as: Riyadh, Montpellier, Belize, At the time of winding, the carbon fiber should be stable and not deviated, and the surface of the mandrel should be uniformly and continuously covered. Arranged according to a certain law, so that adjacent chemical fibers are neither easy to overlap nor have gaps, this law is called "winding law". The winding laws are different, and the quality of the carbon fiber pipes is also different. The proper design of the winding shape can ensure the quality of the carbon fiber pipes.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.