Factory Supply Solid Composite Plate - custom carbon fiber parts by CNC cutting – Feimoshi

Factory Supply Solid Composite Plate - custom carbon fiber parts by CNC cutting – Feimoshi Detail:

Description:

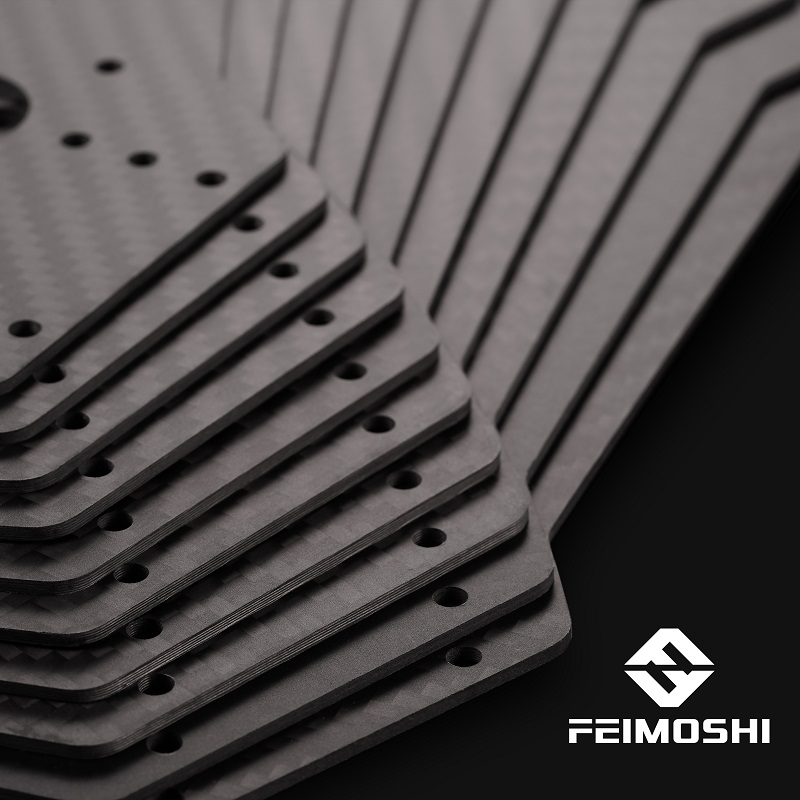

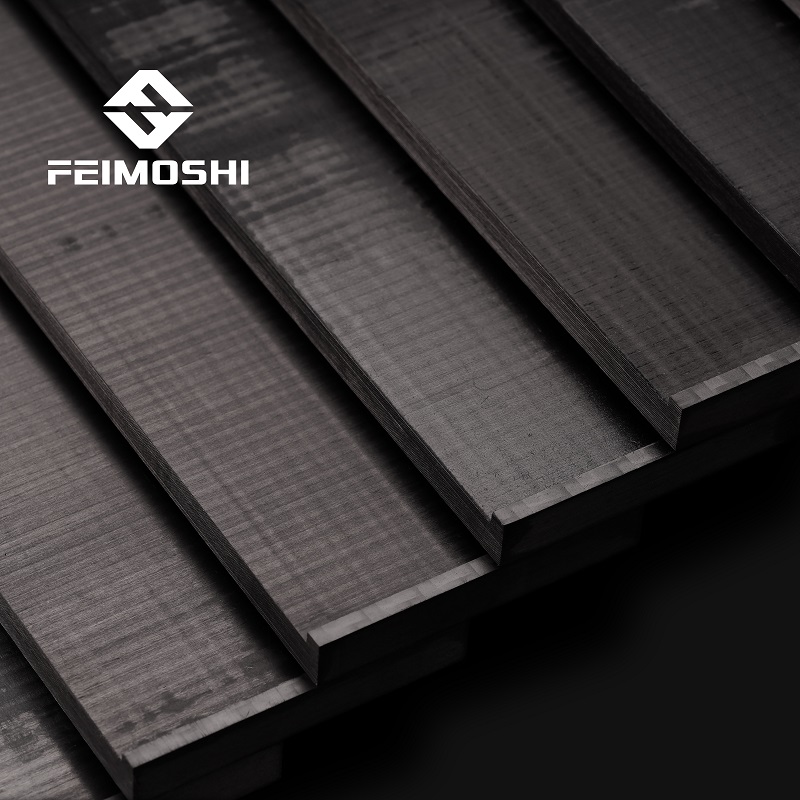

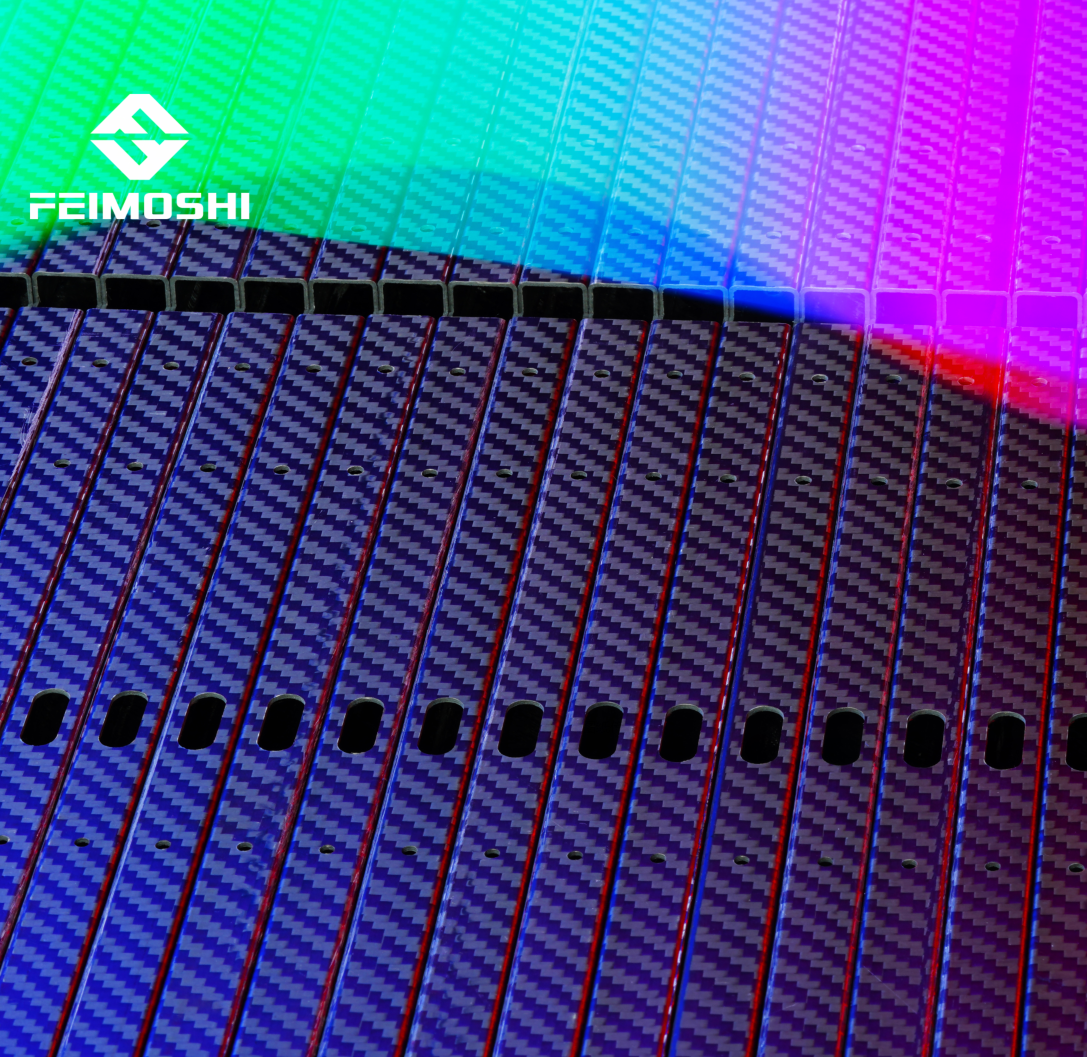

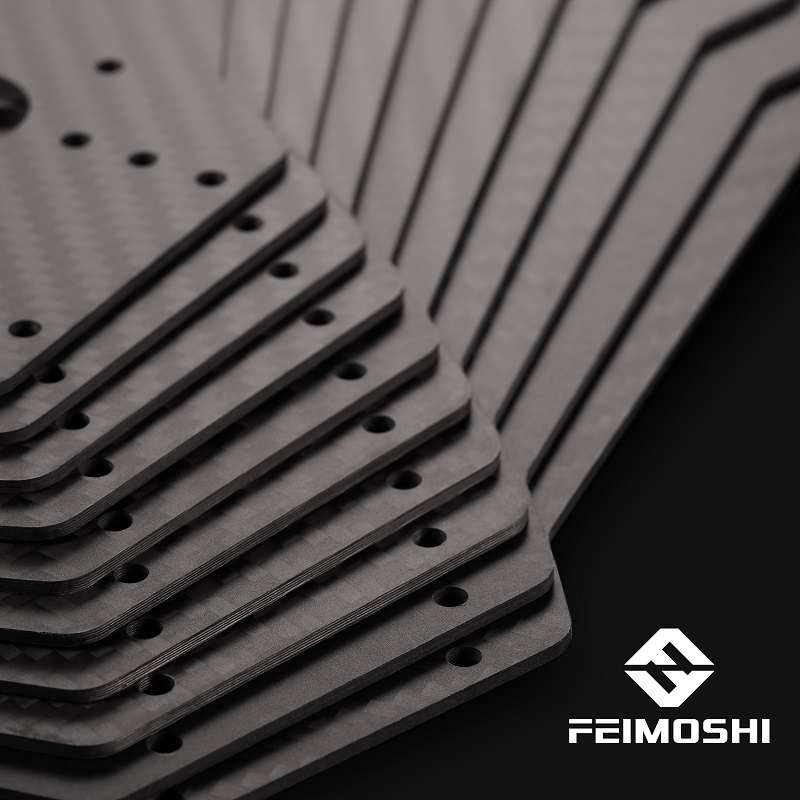

Cnc Carbon Fiber Cutting parts are made of carbon fiber plate through CNC machining. Compared with other materials, carbon fiber has more outstanding features, such as high strength, light weight, anti-aging, it’s widely used in different fields. We supply customized carbon fiber CNC machining service according to your drawings.

CNC service:

We are professional in carbon fiber plates and carbon fiber sheets CNC cutting for Drones /FPV for more than 10 years

We have been cooperating with lots of famous brand.

We do cutting according to our customers’ design(file with .dxf format) and we protect each design for our customers.

Product detail pictures:

Related Product Guide:

Carbon fiber greatly improves the characteristics of special-shaped parts. At this stage, carbon fiber special-shaped products have many requirements in the fields of unmanned aircraft, auto parts, intelligent robots, etc. Factory Supply Solid Composite Plate - custom carbon fiber parts by CNC cutting – Feimoshi , The product will supply to all over the world, such as: Bangladesh, Moscow, Mecca, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

Send your message to us:

Write your message here and send it to us