Hot New Products Drill Composite Tube - 30mm custom carbon fiber octagonal tube – Feimoshi

Hot New Products Drill Composite Tube - 30mm custom carbon fiber octagonal tube – Feimoshi Detail:

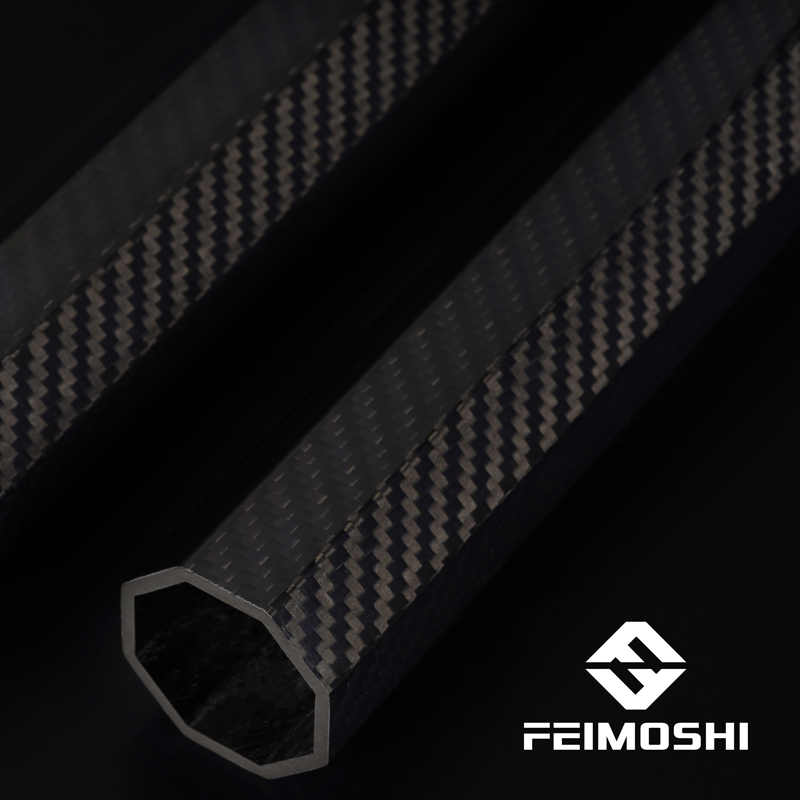

30mm custom carbon fiber octagonal tube

Carbon tube/pipe features:

1. Introduction

These 3K Octagonal Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill or plain weave; Available in different colors and sizes( usually 3K twill matte); Customized Round tube specs are accepted, like Outer Diameter: 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 20mm, 22mm, 25mm, 30mm……350mm;

Customized Shaped Carbon Fiber Tube: such as: 20X30mm, 30X30mm or others. Thickness: 1.0mm, 1.5mm, 2.0mm or other thickness.

Length:

Recently we upgrade our machines to improve the carbon fiber tube precision.

Most precise tolerance shaped carbon fiber tubes for us.

2. Specifications

1) High temperature resistance carbon fiber tubes:100%carbon fiber ;

2) Light & high strength;

3) Good corrosion resistance;

After the use of carbon fiber drone components, not only the weight of the drone is reduced, but also the load, flight time and distance of the drone have been greatly improved. According to carbon fiber customer case analysis in recent years, the demand for carbon fiber pipes is mainly concentrated in the fields of unmanned aerial vehicles, automotive rail transit, industrial machinery, etc. The original intention of their applications is mostly lightweight.

Looking at the entire UAV market, we will find that lightweight is the most intuitive purpose, but ultimately, the performance of UAVs must be improved through lightweight. In fact, in addition to lightweight, because the linear expansion coefficient of carbon fiber materials is almost “0″, in some thermally sensitive areas, temperature changes will have a certain impact on measurement accuracy. High-end aerospace instruments need to pay special attention to this. The low creep of carbon fiber tubes can meet this demand.

Therefore, lightweight is the main purpose of the application of carbon fiber tubes, but it is not limited to this point. The physical and chemical properties of carbon fiber tubes are relatively excellent, and the ultimate goal is to achieve the overall performance of the equipment through it.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal Carbon Fiber Pipe Cost Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fibre Tube 30mm are quality guaranteed. We are China Origin Factory of Carbon Fiber Charge Pipe. If you have any question, please feel free to contact us.

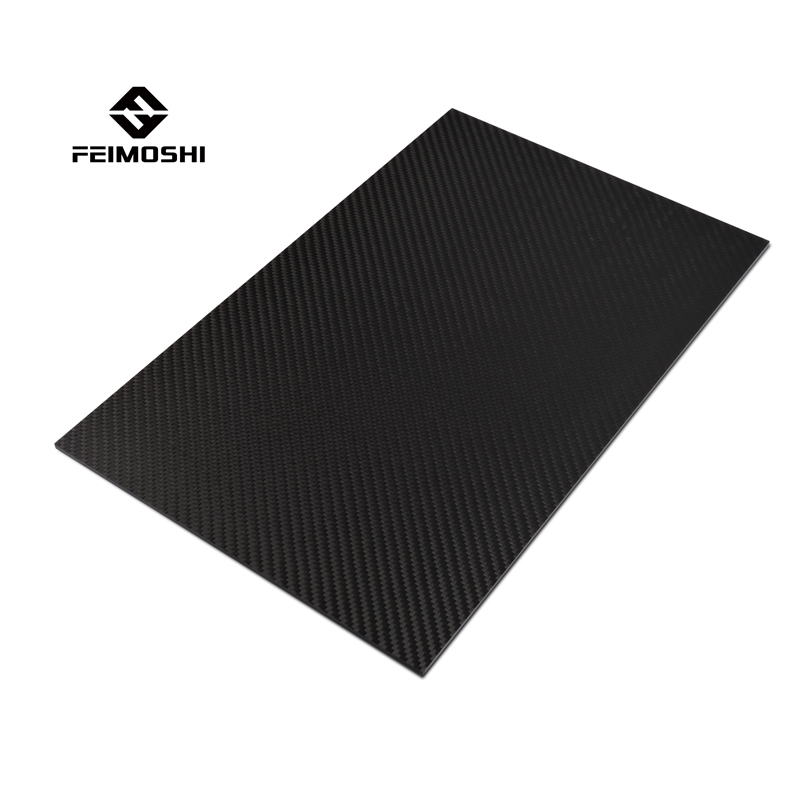

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. Hot New Products Drill Composite Tube - 30mm custom carbon fiber octagonal tube – Feimoshi , The product will supply to all over the world, such as: Angola, Albania, Brunei, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!