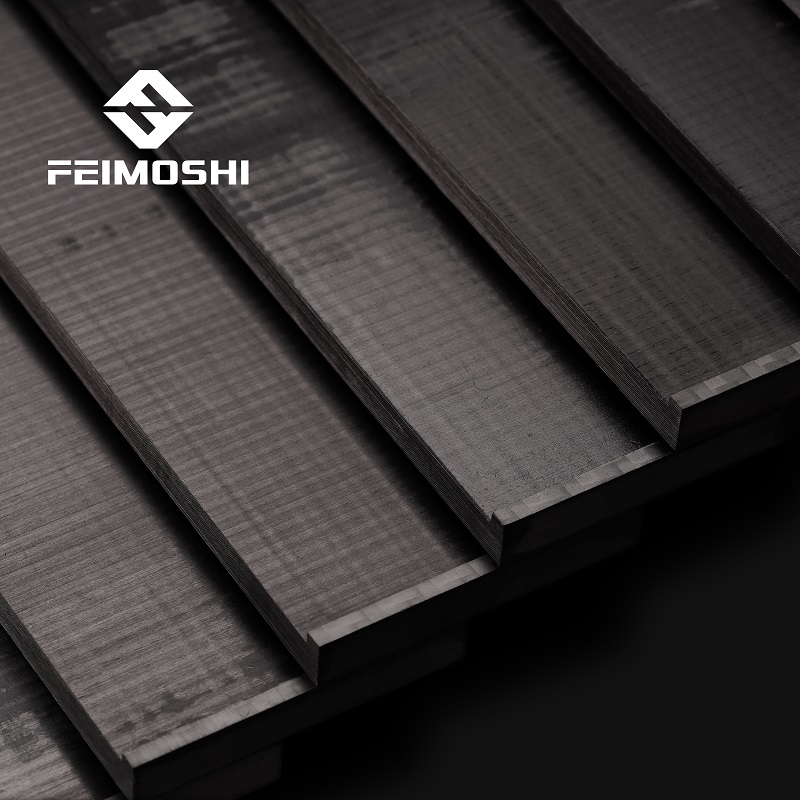

The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Hexagon Carbon Fiber Tube, Carbon Fiber Desktop, Rectangular Carbon Fiber Tube, Carbon fiber products are very light-weight materials. Compared with the same volume of plates, the steel plate material is 4 times heavier than the carbon fiber material. It is precisely because carbon fiber is strong and durable that it is used in many places and is loved by major businesses and people. Let me tell you about the specific performance of the durability of carbon fiber products. 1. Thermal properties. Carbon fiber products can withstand temperatures of thousands of degrees Celsius, so they can be used to make rocket thrusters and some electronic devices that generate high temperatures during operation, and carbon fiber is also a conductive material. 2. Mechanical properties. Ordinary materials are generally heavier, the higher the strength, so that the ability to withstand impact is higher. Carbon fiber products are very light in weight and high in strength. Using them in airplanes or cars can not only reduce weight, but also increase their speed and save fuel. It can also make cars stronger and more reliable. driver's safety. 3. Chemical properties. Carbon is an element with very stable chemical properties. The carbon content in carbon fiber is as high as 90%, so it has good corrosion resistance. Even if it is used in the sea for a long time for decades, there will be no problems. There is no need to worry about carbon fiber products. Rusty condition. 4. Other properties. Carbon fiber products are healthy and non-toxic, and have good penetrating ability to X-rays. Using them on medical bed boards can reduce the side effects caused by radiation and make the imaging clearer. Carbon fiber products have good performance and long service life.

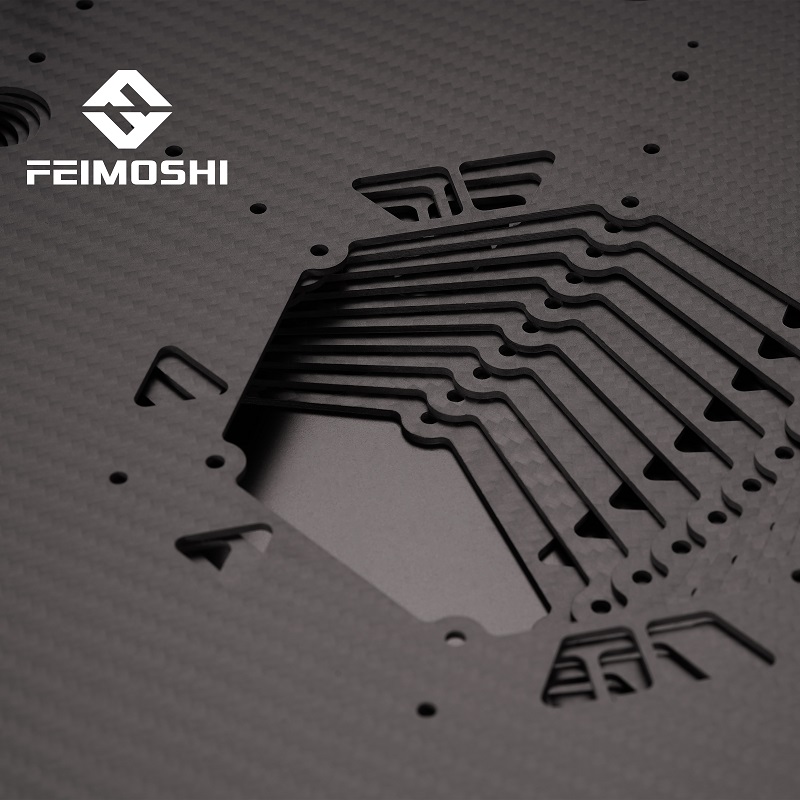

Hot-selling Cnc Cutting Service - CNC machining carbon fiber parts cutting for drone – Feimoshi Detail:

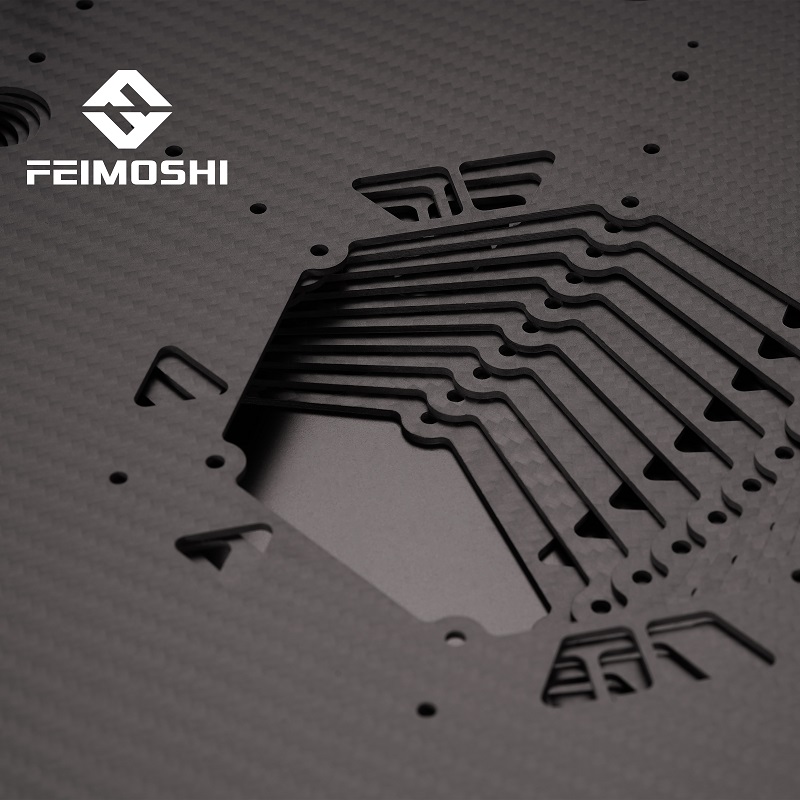

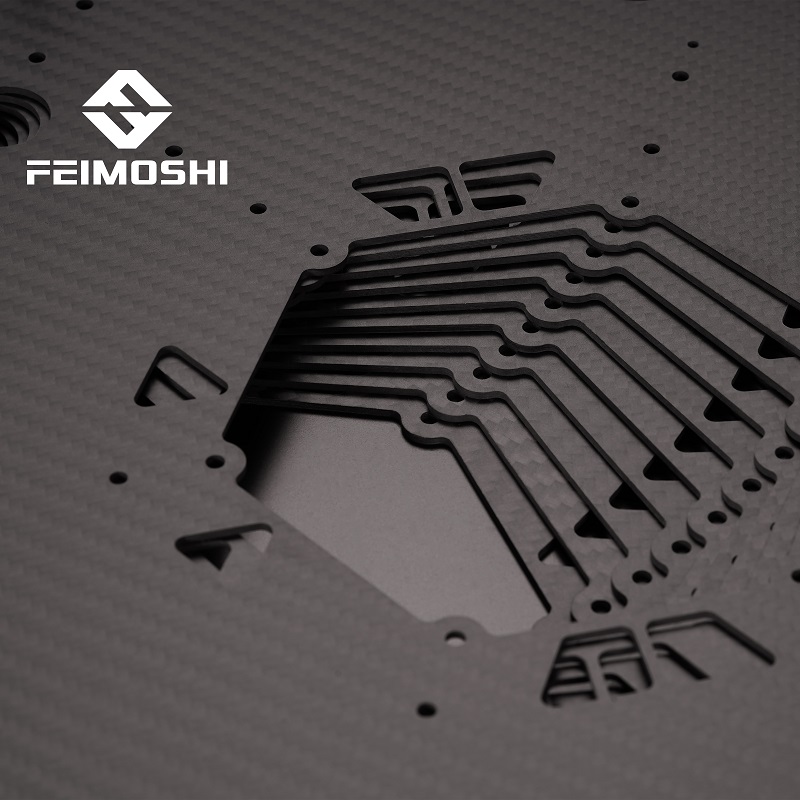

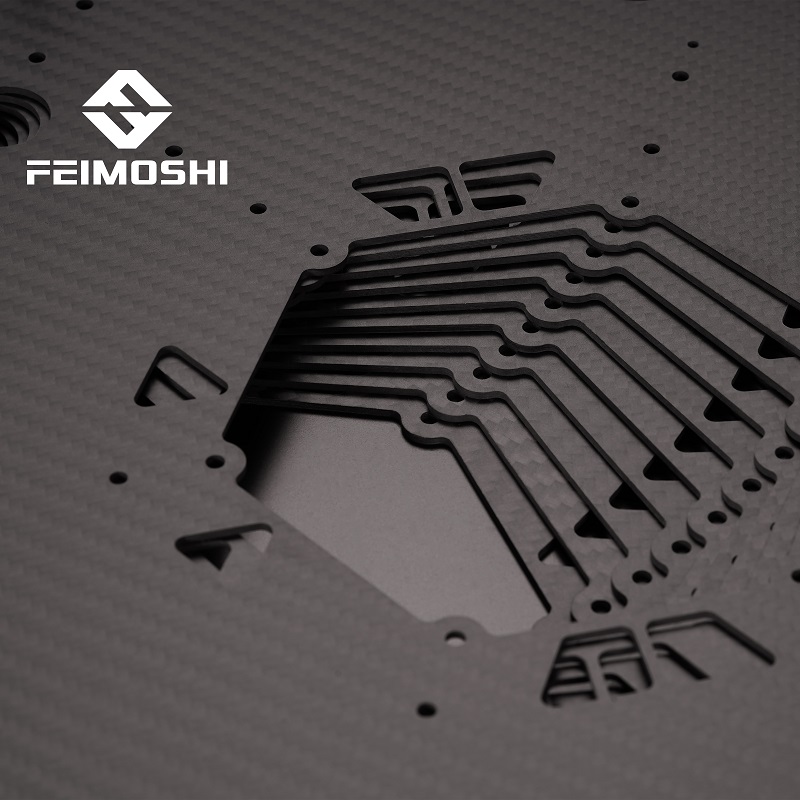

CNC machining carbon fiber parts cutting for drone

FEIMOSHI is a proffessional manufacturer of carbon fiber products, loved by drone customers and our CNC cutting process has won their praise. CNC machining is precision and cost-effective way to achieve innovation and creativity, which triggers out our endless imagination and creative inspiration. We had made so many different carbon fiber CNC parts for racing parts, RC helicopters, bicycle bracket, and reinforcements for 10 years.

Feature:

Surface: Matter/Light/Twill/plain

Size: OEM(STEP, DWG or other)

Material: 100% carbon fiber

Shape: Smooth

Technical: FPV/Drone/UAV/RC Frame

Applications:

1. Aerospace, Helicopters Model Drone ,UAVS, FPV

2. RC model parts

3. Manufacture fixtures and tooling

4. Industrial automation and robotics

5. Sports equipment

6. Musical instruments

7. Scientific apparatus

8. Medical device

9. building construction repair and strengthening

Our service

Any needs, please feel free to contact me!

Express: Fedex, UPS, DHL, TNT

Delivery time: about 5-10 working days

After-sales service

Product detail pictures:

Related Product Guide:

3. Carbon fiber material shock absorber. It is manufactured from epoxy rubber sheet and carbon fiber production, and has the original vibration damping properties of high bending stiffness raw materials. Often in the case of industrial equipment, this type of feature will quickly reduce the vibration caused by sports and fitness, high stability, and improve production efficiency. In addition, it is also helpful for reducing load and extending life. Hot-selling Cnc Cutting Service - CNC machining carbon fiber parts cutting for drone – Feimoshi , The product will supply to all over the world, such as: Angola, Vietnam, Bolivia, The characteristics of carbon fiber tube:1. High tensile strength: The strength of carbon fiber is 6-12 times that of steel, which can reach more than 3000mpa.2. Low density and light weight. The density is only less than 1/4 of steel.