Professional China Carbon Fiber Boom - 3k full carbon fiber license plate black carbon license frame for car – Feimoshi

Professional China Carbon Fiber Boom - 3k full carbon fiber license plate black carbon license frame for car – Feimoshi Detail:

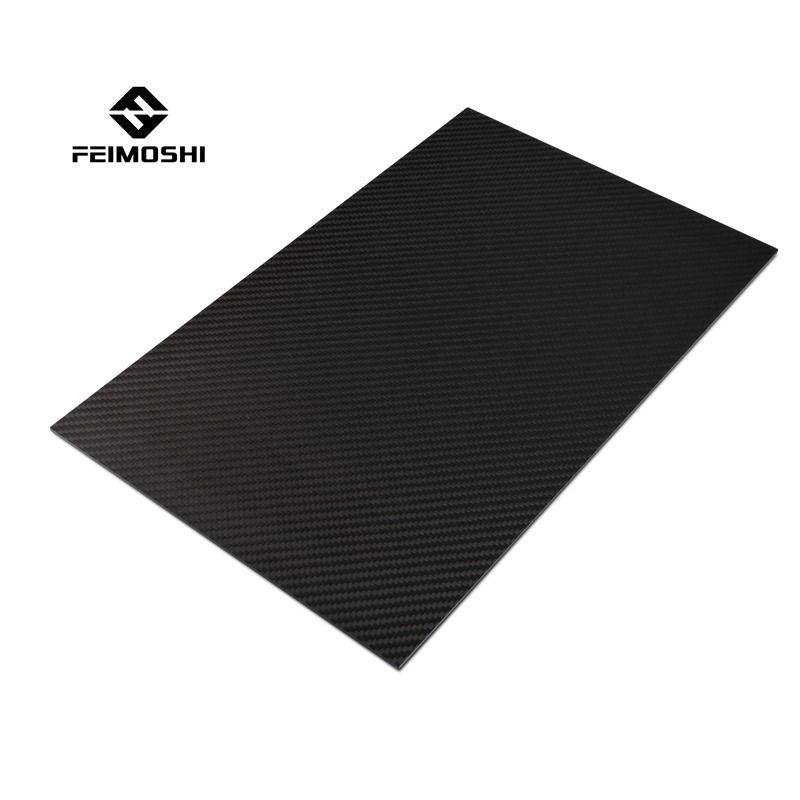

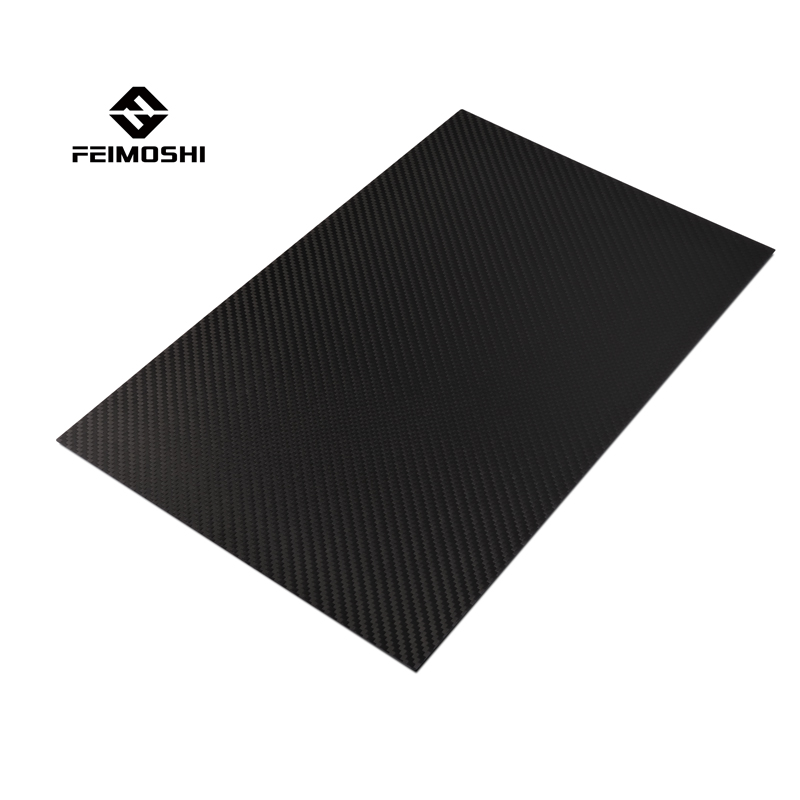

3k full carbon fiber license plate black carbon license frame for car

Custom logo aluminum alloy carbon fiber car USA number license plate frame, support for logo printing, if you want to order big quantity, pls feel free to contact us to obtain more cheaper price

Characteristic:

1. 100% real black carbon fiber license plate frame;

2. Fits the USA and CANADA standard size 6.25″ x 12.25″(159*311mm);

3. Matte Finish and glossy finish for option;

Product detail pictures:

Related Product Guide:

Carbon fiber was produced in the early 1950s in response to the needs of cutting-edge science and technology such as rockets, aerospace and aviation, and is now widely used in sports equipment, textiles, chemical machinery and medicine. With the increasingly stringent requirements of cutting-edge technology on the technical performance of new materials, scientific and technological workers are constantly striving to improve. In the early 1980s, high-performance and ultra-high-performance carbon fibers appeared one after another, which was another leap in technology, and also marked that the research and production of carbon fibers had entered an advanced stage. Professional China Carbon Fiber Boom - 3k full carbon fiber license plate black carbon license frame for car – Feimoshi , The product will supply to all over the world, such as: Dubai, Austria, Romania, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.

Send your message to us:

Write your message here and send it to us