Super Lowest Price Carbon Fiber Construction - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi

Super Lowest Price Carbon Fiber Construction - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi Detail:

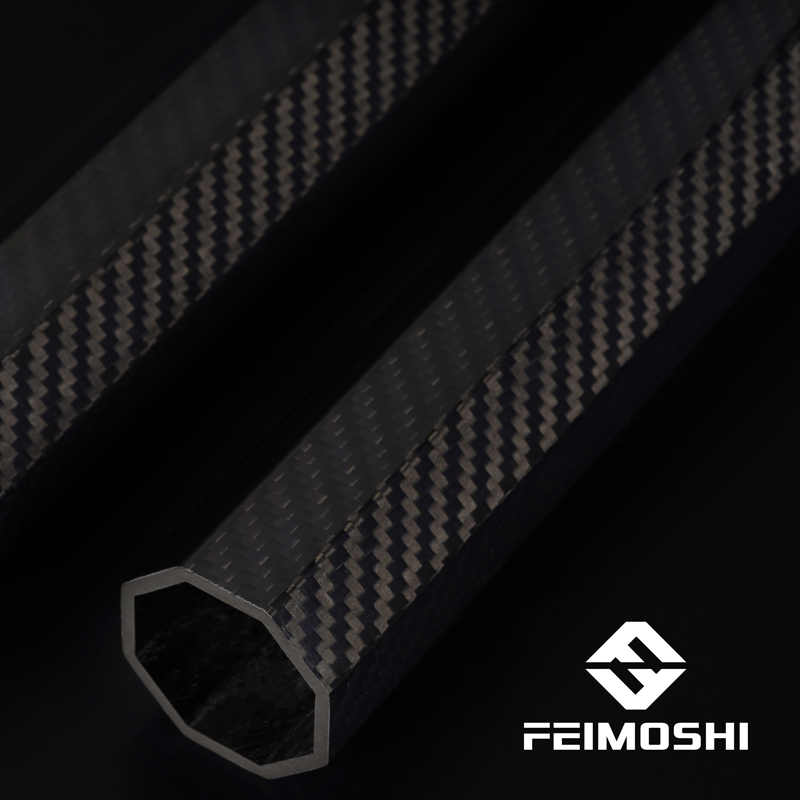

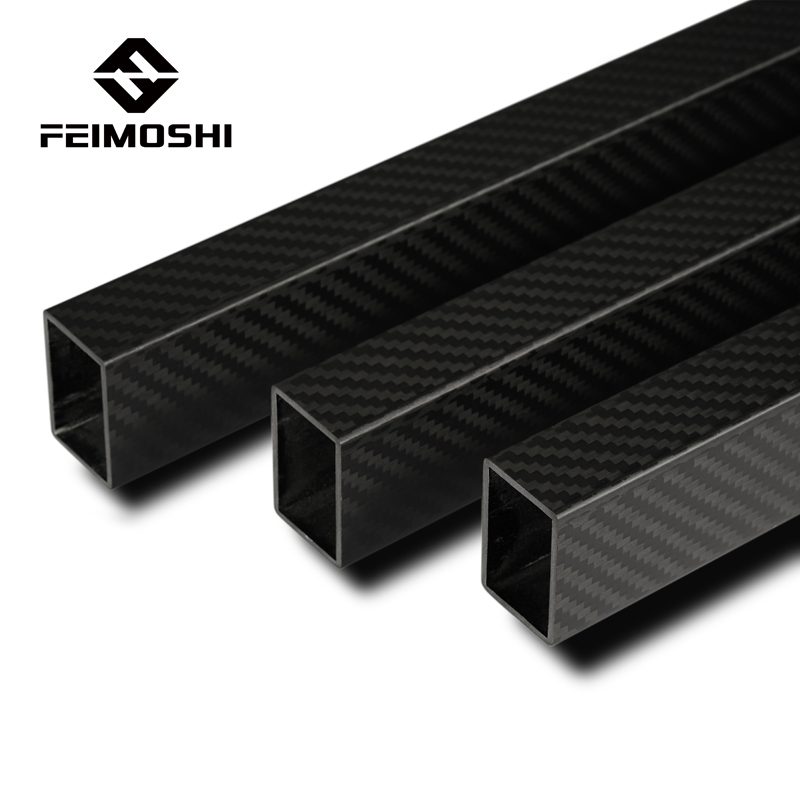

Custom Octagonal composite carbon fiber square tube for accessories

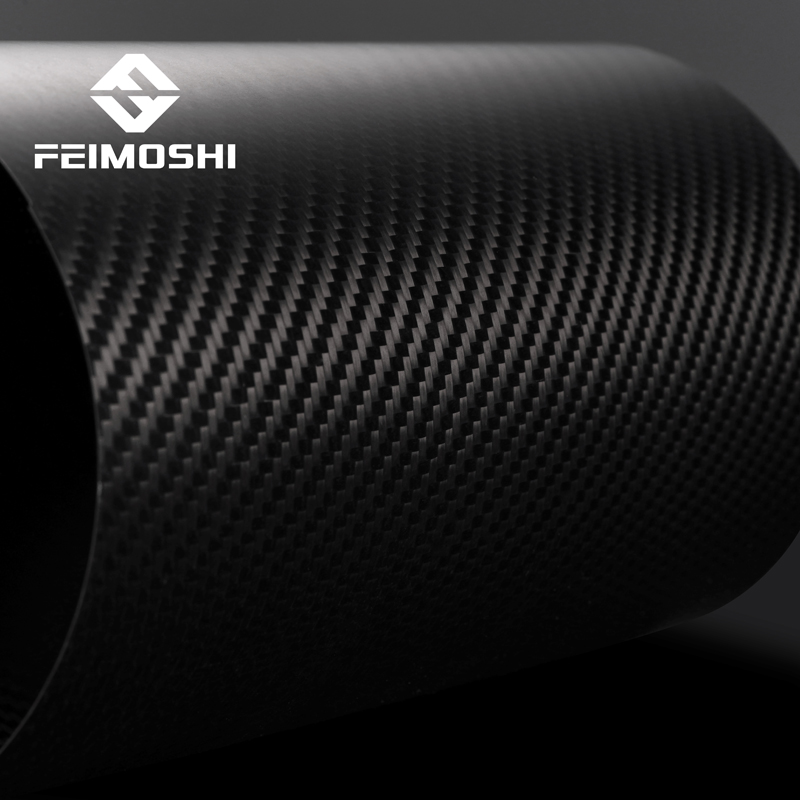

In these recent years, custom carbon fiber tube is more populare in the drone market.

Also we have carbon fiber round tube, carbon fiber octagonal tube and carbon fiber square tube in stock.

Different size and type is avaliable for your choosing.

Small carbon fiber round tube could be inserting the large carbon fiber tube according to your requirements.

Carbon fiber rectangle tube, large carbon fiber tubes, carbon fiber tube handguard, ect. are all customized according to your requirements.

If you have any other requirements, please don’t hesitate to contact us.

Product detail pictures:

Related Product Guide:

Carbon fiber is made of man-made fiber with high carbon content and does not melt during the whole process of heat treatment, and is made by thermal stable oxidation treatment, carbonization treatment and graphitization. In today's economic and social development, carbon fiber has long been widely used as a new material, ranging from aerospace industry equipment raw materials to small handbags and other fields. So why is carbon fiber so popular? What are its actual advantages? Super Lowest Price Carbon Fiber Construction - Custom Octagonal composite carbon fiber square tube for accessories – Feimoshi , The product will supply to all over the world, such as: Hyderabad, Islamabad, Morocco, The winding process of carbon fiber refers to the whole process of winding the carbon fiber raw material soaked in the resin glue on the core mold according to a certain rule, and then drying and solidifying the mold. This forming method is mostly used to make carbon fiber tubes.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Send your message to us:

Write your message here and send it to us