Wholesale Price China Diy Carbon Fiber Tube - High Quality 3k Twill Matte Round or Tapered Carbon Fiber Tube – Feimoshi

Wholesale Price China Diy Carbon Fiber Tube - High Quality 3k Twill Matte Round or Tapered Carbon Fiber Tube – Feimoshi Detail:

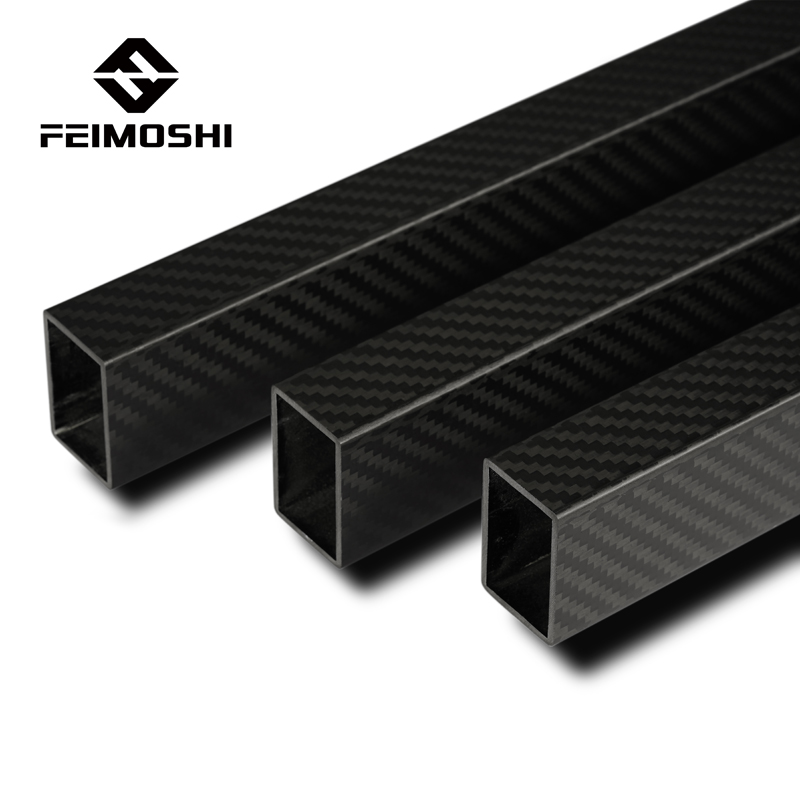

High Quality 3k Twill Matte Round or Tapered Carbon Fiber Tube

Carbon fiber tubes from Tstar can be made by craft of pultrusion, roll wrapped, pull braiding and mould pressing.

Roll wrapped carbon fiber tubes are made by multiple wraps of twill and/or unidirectional carbon fabrics prepreg. Roll wrapped tubes are ideal for applications that require the highest bending stiffness and lowest weight, such as automation robotics, telescoping poles and UAV components. The finish of roll wrapped tube can be glossy or matte with 3K weave or uni-directional pattern.

Product detail pictures:

Related Product Guide:

Carbon fiber is made of man-made fiber with high carbon content and does not melt during the whole process of heat treatment, and is made by thermal stable oxidation treatment, carbonization treatment and graphitization. In today's economic and social development, carbon fiber has long been widely used as a new material, ranging from aerospace industry equipment raw materials to small handbags and other fields. So why is carbon fiber so popular? What are its actual advantages? Wholesale Price China Diy Carbon Fiber Tube - High Quality 3k Twill Matte Round or Tapered Carbon Fiber Tube – Feimoshi , The product will supply to all over the world, such as: azerbaijan, Portugal, Gambia, Cutting Carbon Fiber Laminates: Carbon fiber plastic sheets can be cut with standard tools ranging from scissors and razor blades to thinner plastic sheets, milled cut-off wheels and dremel tools. For cutting many carbon fiber double plates, we propose to use carbide cutting tools, wear-resistant material type cutting machines or diamond film-forming tools. Basic steel tools can cut carbon plates, but because of the breakage characteristics of all aluminum alloy plates, standard tools can quickly break down in extra-heavy cutting applications. The control panel can then be simply sanded and polished, allowing you to trim the close and sanded edges to final specifications to maintain a clean, uncluttered edge.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

Send your message to us:

Write your message here and send it to us