2021 High quality Carbon Fiber Panel Sheet - Custom 100% Carbon Fiber cutting accessories – Feimoshi

2021 High quality Carbon Fiber Panel Sheet - Custom 100% Carbon Fiber cutting accessories – Feimoshi Detail:

Model No.: Carbon fiber cutting accessories

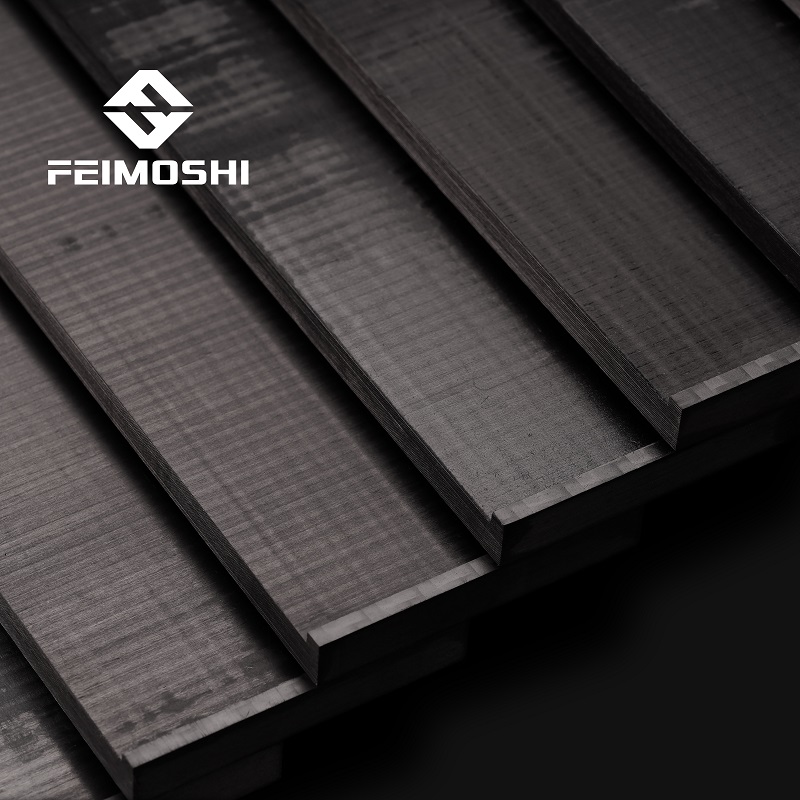

Shape: Carbon Fiber Plate for cutting

Performance: High-Strength and Light weight

Mechanical Property: High-Performance Type

Transportation: DHL/Fedex/EMS/HK post/Epacket or others

Place of Origin: Shenzhen

Payment Type: T/T, Paypal, Western Union

Incoterm: FOB, CFR, EXW

Delivery Time: 7-15 working Days

CNC Carbon Fiber Cutting is a special way to help customers get the unique frame to produce their drones in the market. We made many cooperation with many popular brand and also get more and more good feedback.

Carbon fiber plate could have the advantage of light weight and high strength. We could customize different size and type carbon fiber plate for cutting. CNC cutting carbon fiber accessories is widely used in our daily life.

More quantity, more competitive price for your FPV/handguard/structure/furniture,ect.

Product Description

Material: Carbon fiber part Size :Customized (welcome to customeied)

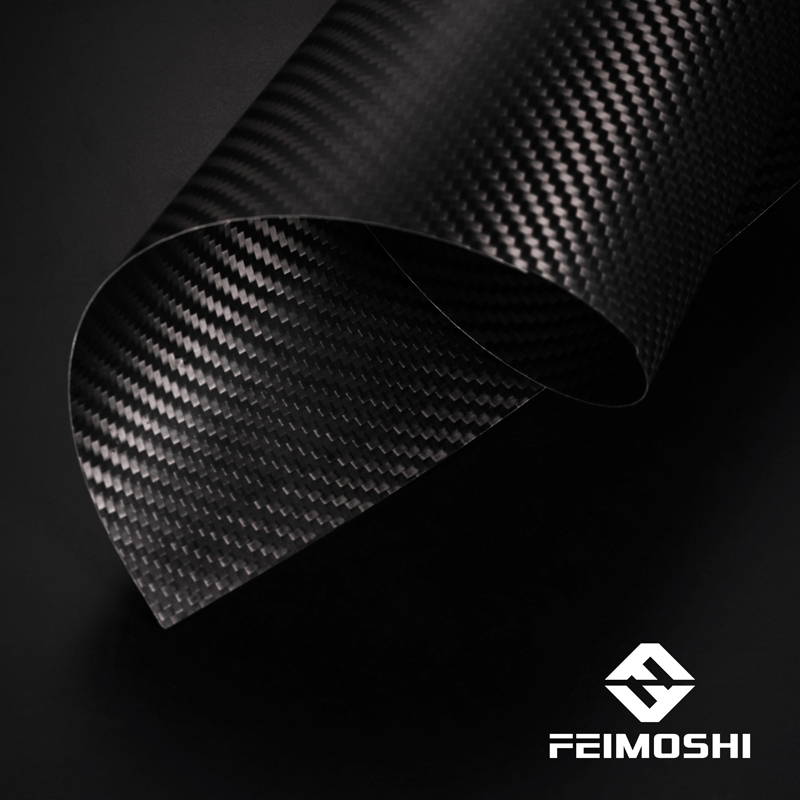

Surface: Twill/Plain Matte/Glossy or other colors

Stock: Normal plate are in stock(400X500mm or 500X600mm)

Service: OEM & ODM,Cnc Cutting Service And Logo Printing

Looking for ideal CNC 3K Carbon Fiber Sheet Manufacturer & supplier ?

A: We have a wide selection at great prices to help you get creative. All the 3K Carbon Fiber Sheet Plate are quality guaranteed. We are China Origin Factory of CNC Cutting Carbon Fiber Sheets. If you have any question, please feel free to contact us.

Looking for ideal 100% Carbon Fibe Manufacturer & supplier ?

A: We have a wide selection at great prices to help you get creative. All the Low Price CNC Cutting are quality guaranteed. We are China Origin Factory of Custom Cnc Cutting Service. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. 2021 High quality Carbon Fiber Panel Sheet - Custom 100% Carbon Fiber cutting accessories – Feimoshi , The product will supply to all over the world, such as: Bhutan, Honduras, Haiti, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.