2021 High quality Octagonal Composite Tube - 3K Full Carbon Fiber round Tubes desgin – Feimoshi

2021 High quality Octagonal Composite Tube - 3K Full Carbon Fiber round Tubes desgin – Feimoshi Detail:

3K Full Carbon Fiber Tubes and Connectors

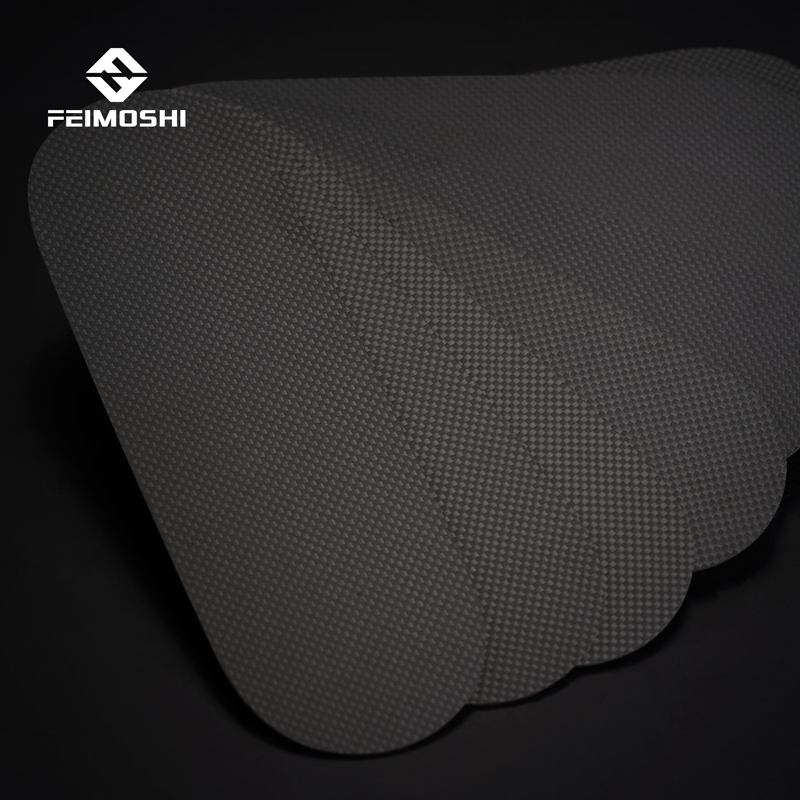

Carbon Fiber Tube has been widely used in hitech fields, such as aerospace, modern sewing machinery, petrochemical industry, medical machinery, automobiles, machinery manufacturing, construction, sports and entertainment items, telecommunication, electrical heating etc.

Carbon fiber roll wrapped tubes are ideal for all kinds of construction projects that require a light weight high performance sporting tube that can deal with forces from any direction.

Any intersting in pls feel free let us know.

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal 3K Full Carbon Tubes Manufacturer & supplier? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Booms are quality guaranteed. We are China Origin Factory of Carbon Tubes and Connectors. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

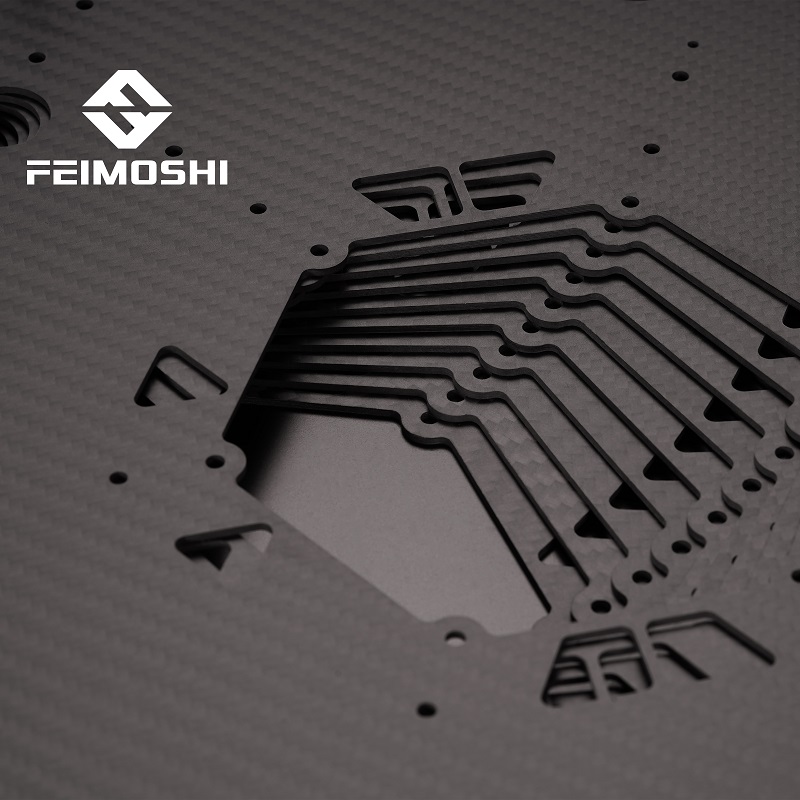

Chopped carbon fiber has high strength, high modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non-oxidizing environment, good fatigue resistance, good electromagnetic shielding, and does not swell or swell in organic solvents, acids and alkalis. Excellent corrosion resistance. 2021 High quality Octagonal Composite Tube - 3K Full Carbon Fiber round Tubes desgin – Feimoshi , The product will supply to all over the world, such as: South Korea, Riyadh, Puerto Rico, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!