The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Carbon Fiber Frame, Real Carbon Fiber Desk, Rc Frame, Carbon fiber can be divided into polythiophene-based carbon fiber, bitumen-based carbon fiber, viscose-based carbon fiber, phenolic resin-based carbon fiber, and gas chromatography-grown carbon fiber according to the source of raw materials; Model and very high solid model carbon fiber; divided into long filament, short fiber and chopped fiber according to the situation; divided into general-purpose and high-performance type according to structural mechanical properties. Universal carbon fiber has a strength of 1000Mpa and a modulus of up to 100GPa. High-performance carbon fiber is divided into high-strength type (strength 2000Mpa, modulus 250GPa) and high solid model (modulus above 300GPa). Those whose strength exceeds 4000Mpa are also called ultra-high-strength models; those whose modulus exceeds 450Gpa are called extremely high solid models. Along with the development trend of the aerospace and aerospace industries, high-strength and high-elongation carbon fibers have also been produced, with a tensile strength of more than 2%.

Best quality Custom Carbon Fiber Tubes - Carbon fiber drone tube – Feimoshi Detail:

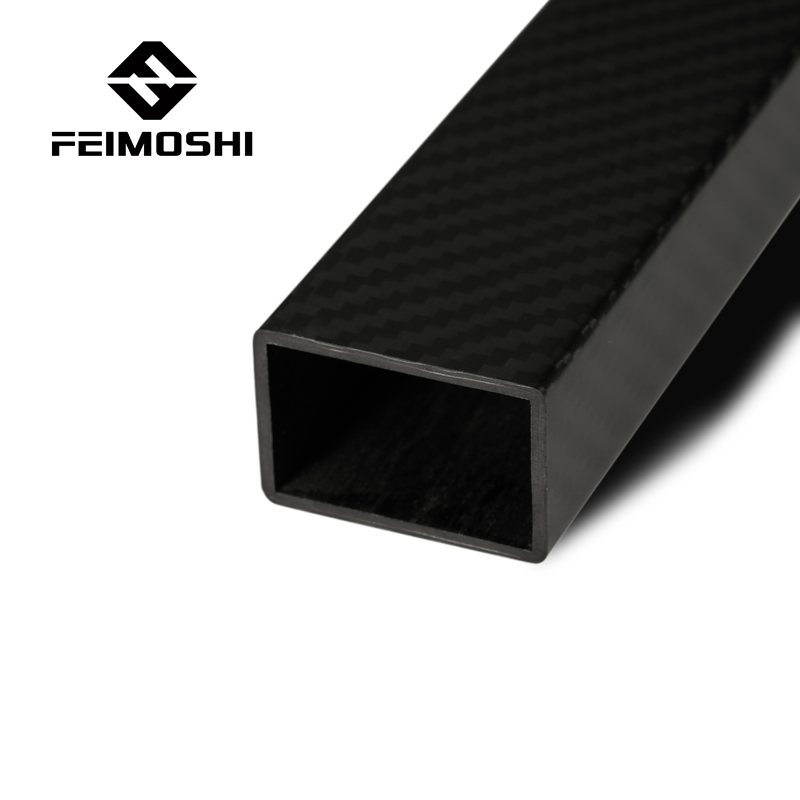

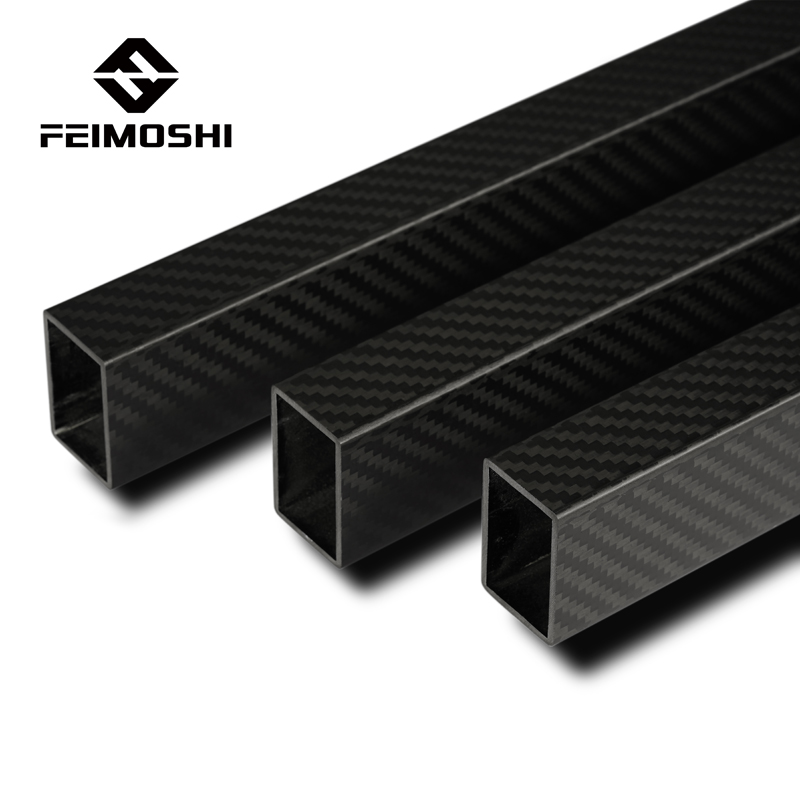

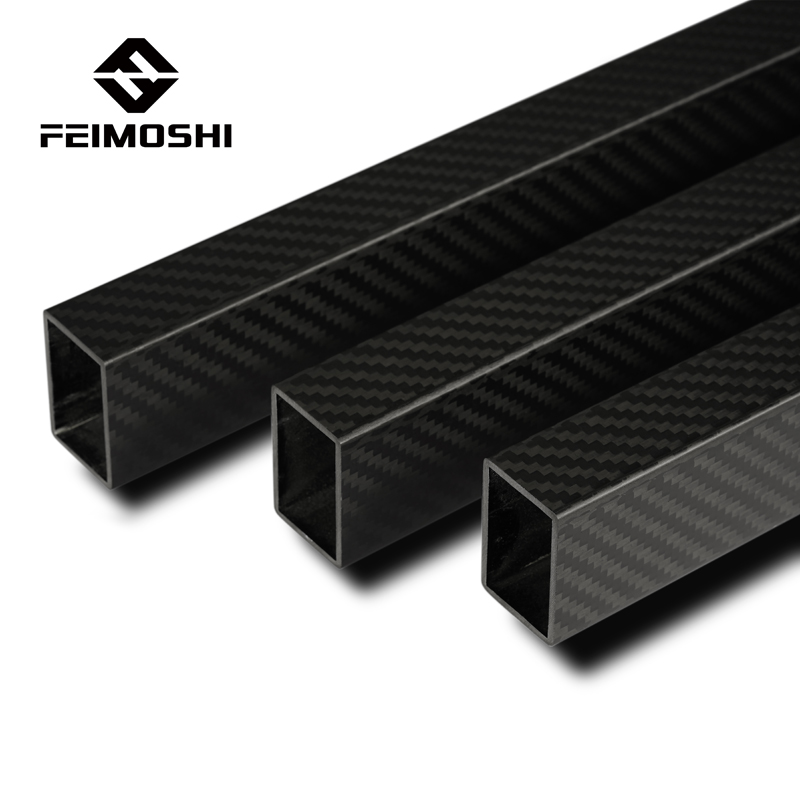

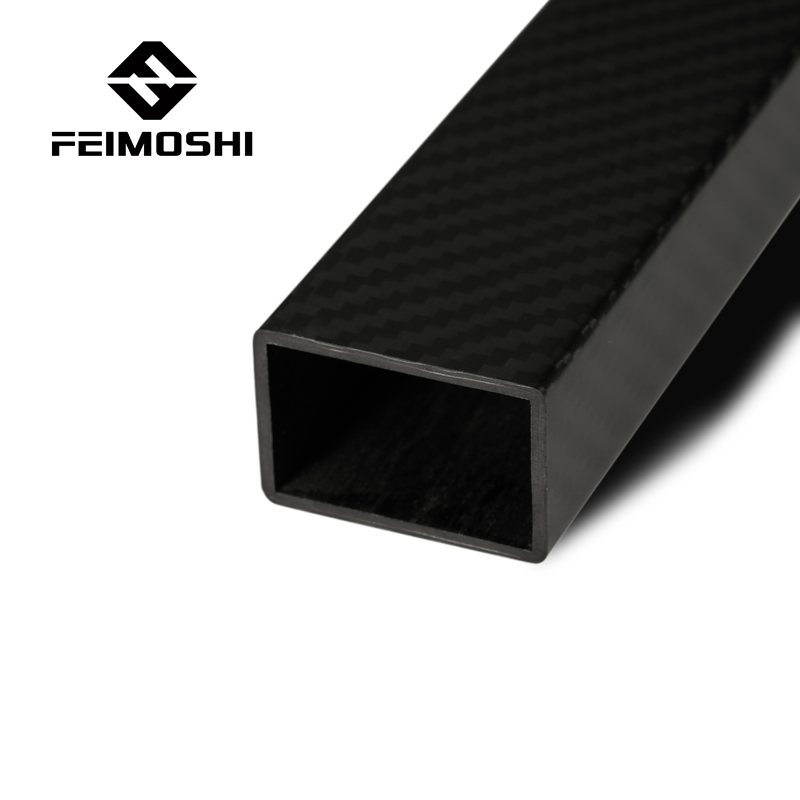

Carbon fiber drone tube

Description:

We use toray carbon wire to make full carbon fiber tube. Good surface and high stiff.

Most of the round tube are in our stock.

The longest length is our stock is 1000mm and we could cut it any length. if customer need the length above 1000mm, we could customize it for you.

Surface: Glossy or Matte. (Matte sell better as glossy is easy to scrach)

Weave: plain and twill

Size: many size are in our stock

Length: 1000mm or other

Product detail pictures:

Related Product Guide:

Carbon fiber board is a composite material composed of carbon fiber filaments and resin. The resulting product is lightweight, yet strong and durable. Carbon fiber sheets come in many different types to suit a variety of applications and industries, including automotive and aerospace. Best quality Custom Carbon Fiber Tubes - Carbon fiber drone tube – Feimoshi , The product will supply to all over the world, such as: California, San Diego, Latvia, For special parts with complex shapes, a series of processes such as carbon fiber prepreg laying, curing and molding can be performed only after the mold is completed, and finally the finished carbon fiber special shape parts are produced. During this period, strict planning, raw material selection, mold quality, construction quality control and other links are required, and any negligence in any link will affect the final quality of the product.