High definition Aluminum Composite - 3K full Carbon Fiber Sheet Frame for CNC Cutting – Feimoshi

High definition Aluminum Composite - 3K full Carbon Fiber Sheet Frame for CNC Cutting – Feimoshi Detail:

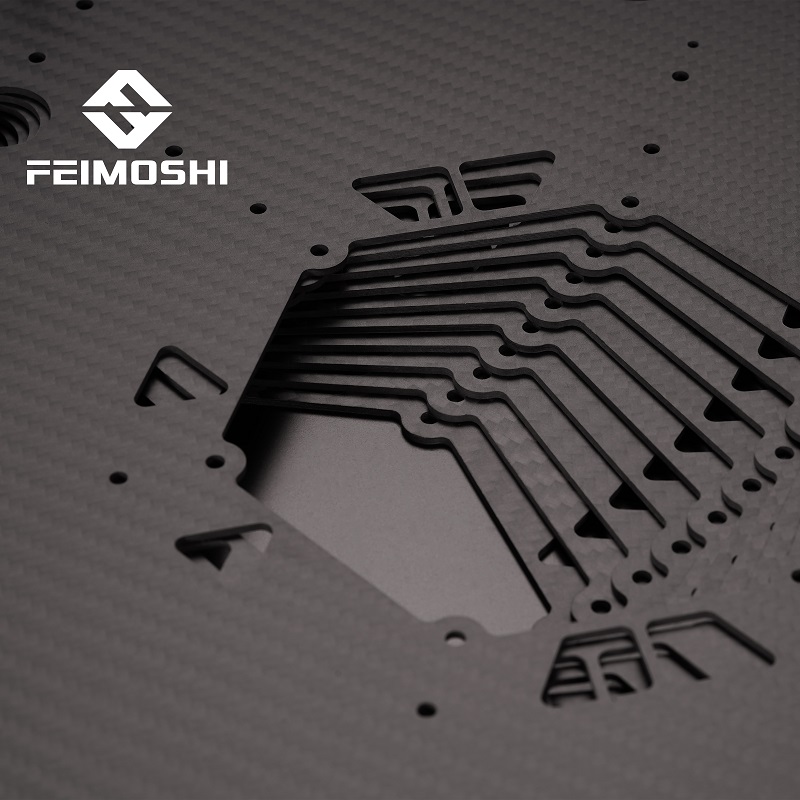

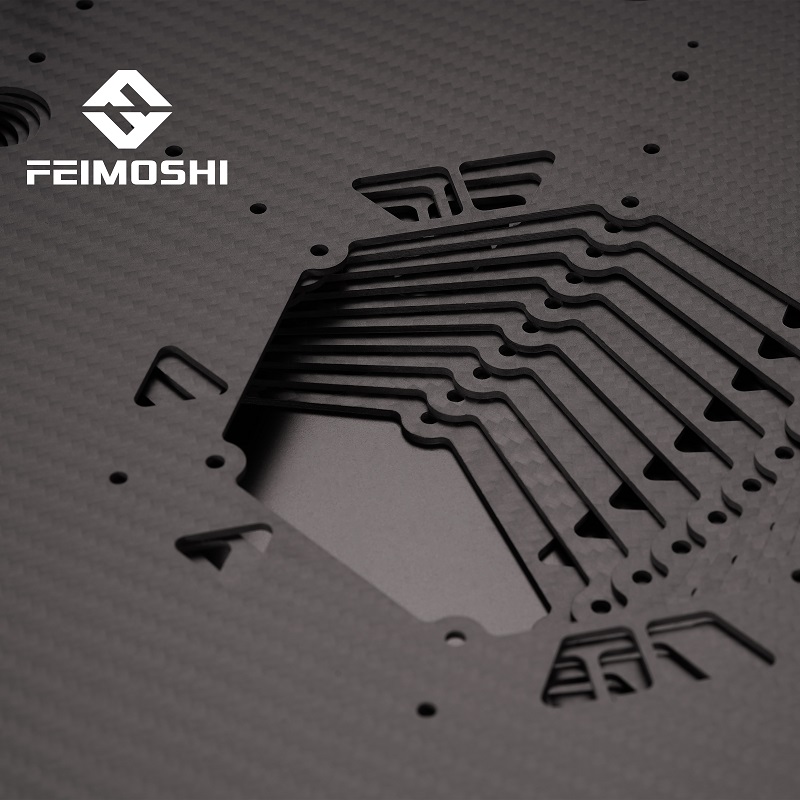

3K full Carbon Fiber Sheet Frame for CNC Cutting

This is pure carbon fiber sheet, 2.0mm Carbon Fiber Sheet Frame for CNC Cutting is most popular in carbon fiber materials. Both 0/90 degree and 0/45/-45/90 degree (Quasi-isotropic)layout are available. Because of the light weight, it 2.0mm Carbon Fiber Sheet Frame for CNC Cutting becomes very popular in drone, UVA, FPV market, and it has more and more application now.

Full Carbon Fiber Sheet, Carbon Glass Fiber, G10 Glass Fiber Sheet all in stock.

Any questions of CNC cutting or OEM service pls feel free to contact us.

Advantage: We have a professinal engineer team to research it. Have enough quantity in stock, shipping fast. Making your frame more professinal and stronger. Bulk order have more discount for our customers.

Shipping information: We had a good forwarder for express,always fast shipping with a good price Usually DHL is the best Fedex/UPS/TNT are ok

We are profession carbon fiber factory in more than ten years experience. There are many branded company that are cooperated with us in about ten years. Our engineer has the professional technology to deal with the carbon fiber cutting problem and offer the detailed solution for our customers when using it. Carbon fiber cloth could do various products, like carbon fiber sheet, carbon fiber tube, carbon fiber furniture, carbon fiber guitar, carbon fiber table, carbon fiber keyboard, carbon fiber rc chassis plate, carbon fiber wallet, carbon fiber skateboard and so on.

Looking for ideal CNC Carbon Fiber Sheet Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Carbon Fiber Sheet CNC Cutting are quality guaranteed. We are China Origin Factory of CNC Cutting Frame. If you have any question, please feel free to contact us.

Product detail pictures:

Related Product Guide:

Composite materials composed of carbon fiber and epoxy resin have become an advanced aerospace material due to their small specific gravity, good rigidity and high strength. Because every kilogram of the weight of the space vehicle is reduced, the launch vehicle can be reduced by 500 kilograms. Therefore, there is a race to adopt advanced composite materials in the aerospace industry. There is a vertical take-off and landing fighter, and the carbon fiber composite material used in it has accounted for 1/4 of the weight of the whole aircraft and 1/3 of the weight of the wing. According to reports, the key components of the three rocket thrusters on the US space shuttle and the advanced MX missile launch tube are all made of advanced carbon fiber composite materials. High definition Aluminum Composite - 3K full Carbon Fiber Sheet Frame for CNC Cutting – Feimoshi , The product will supply to all over the world, such as: Estonia, Slovak Republic, Greece, Molded carbon fiber square tube: The carbon fiber square tube is turned into a rectangular tube, and the prepreg layer is carried out through a rectangular mold. First, according to the size of the square tube, the mold is made, and the prepreg is cut, and then layer by layer. Lay the carbon fiber prepreg on top of the square tube, each layer of prepreg can complete a circle of the square tube, after the layup is completed, the mold is clamped and fixed, and then sent to the curing equipment to complete the curing, and so on. After that, the mold is disassembled, and the core mold is demolded to obtain a carbon fiber square tube.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.