High definition Composite Plate Fit - 3K full fpv carbon fiber plate for drone – Feimoshi

High definition Composite Plate Fit - 3K full fpv carbon fiber plate for drone – Feimoshi Detail:

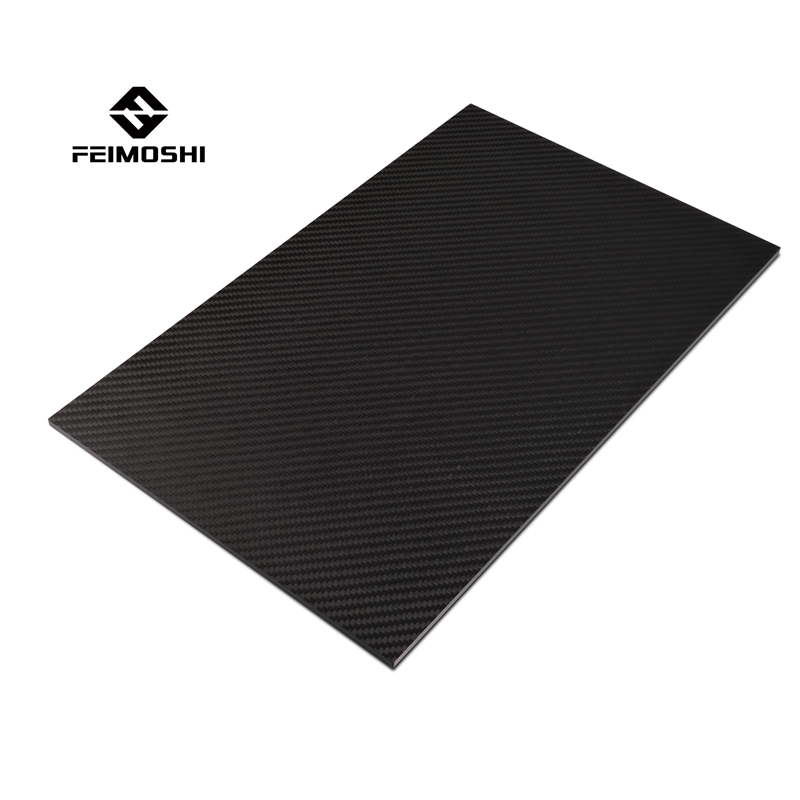

fpv carbon fiber plate

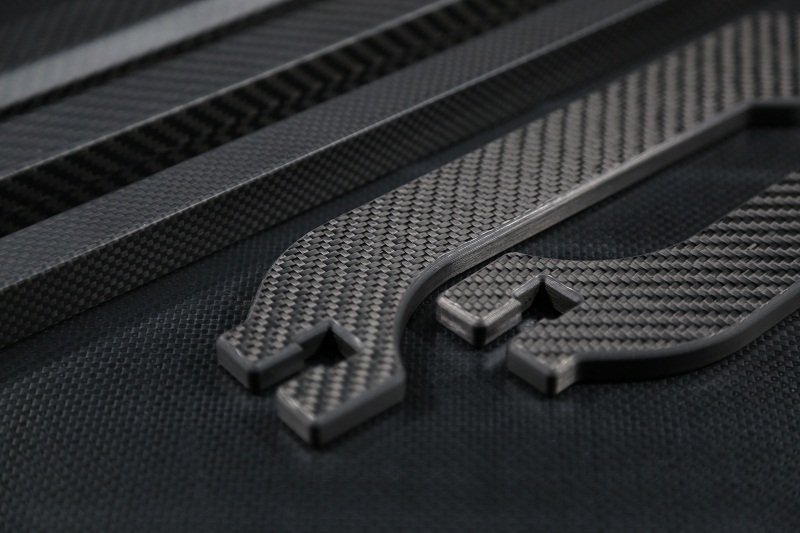

The surface of the full Carbon Fiber Sheet is made using 2X2 twill weave 3k carbon fiber and unidirectional carbon in between orientated at +/- 45 degrees. This construction has a high stiffness advantage. It is the highest grade carbon fiber sheet available. The manufacturing process we use gives a perfect finish, without pinholes or surface imperfections. Full Carbon Fiber Board is available in different thicknesses and sizes, to suit your requirement.

We are a professional manufacturer of CFRP products,locating in Shenzhen City, Guangdong Province where closely to Hongkong. Our products cover a wide range of formations, including GFRP (Glass-fiber-reinforced polymer), CFRP (Carbon-fiber-reinforced polymer) and KFRP (Kevlar-fiber-reinforced polymer) sheets, roll-wrapped tubes, battens, complex profiles as well as 3D shape carbon fiber parts, all in large varieties of dimensions. The products are extensively applied to Construction,Drone,RC control,Helicopters etc.

The principles of our company is keeping credit based on confidentiality and quality, upholding customer prior and service supreme. If you need, we could sign NDA agreement for better cooperation.Considering these, lots of our customers are branding businesses.We warmly welcome your consultation.You will be quite satisfied with our quality products at reasonable prices, together with sincere service. We are looking forward to cooperating with you for mutual benefit here.

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. High definition Composite Plate Fit - 3K full fpv carbon fiber plate for drone – Feimoshi , The product will supply to all over the world, such as: Rio de Janeiro, Mecca, Cannes, Carbon fiber board can directly process flat parts, which is relatively simple. In the design, it is best to use a comprehensive molding design structure to optimize the structure as much as possible. Because carbon fiber composites have poor toughness and are not resistant to mechanical friction, metal connections are usually required to achieve combined structures between parts.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.