High Quality Composite Tube - factory high strength 3K hollow round Carbon Fiber Tube 1000mm – Feimoshi

High Quality Composite Tube - factory high strength 3K hollow round Carbon Fiber Tube 1000mm – Feimoshi Detail:

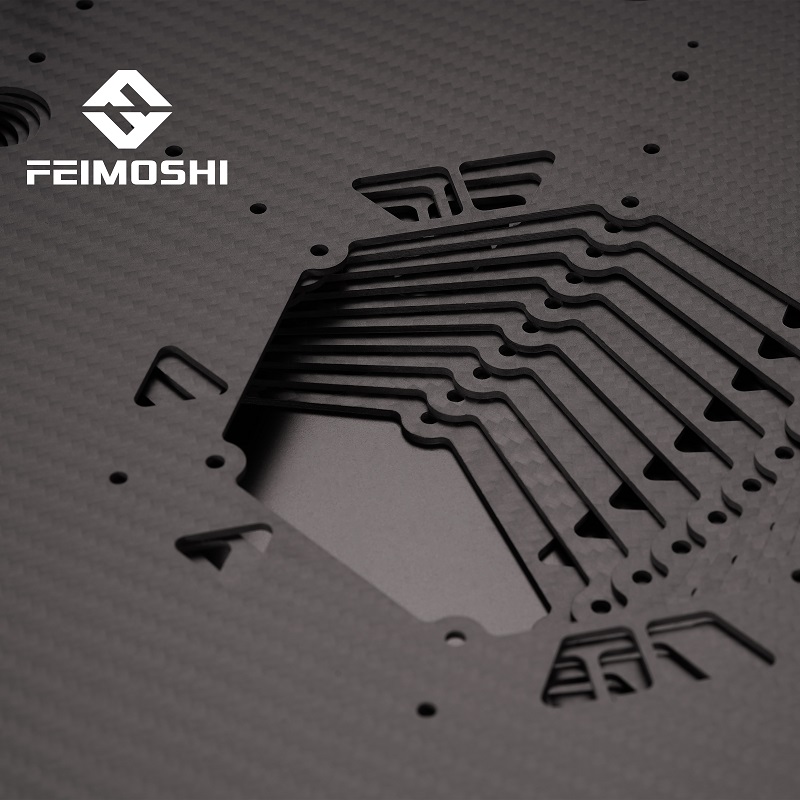

Factory high strength 3K hollow round Carbon Fiber Tube 1000mm

The main purpose of carbon fiber is to compound with resin, metal, ceramics and carbon as a reinforcing material to make advanced composite materials. Carbon fiber reinforced epoxy resin composites have the highest strength and specific modulus among existing engineering materials. Carbon fiber high temperature resistance ranks first among all chemical fibers.

Carbon fiber tubes have a wide range of uses, and can be made into aircraft skeleton beams, arrow shafts, formula racing structural parts, fishing rods, robotic arms, transmission shafts, etc.

Payment Type: T/T, Paypal, Western Union

Incoterm: EXW

Min. Order: 10piece

Delivery Time: 10-25 working Days

Transportation: DHL/Fedex/TNT/Epacket

Port: Shenzhen

Product detail pictures:

Related Product Guide:

The main purpose of carbon fiber is to composite with resin, metal, ceramic and other matrix to make structural material. Carbon fiber reinforced epoxy resin composite materials have the highest specific strength and specific modulus comprehensive indicators among existing structural materials. In the fields with strict requirements such as density, stiffness, weight, fatigue properties, etc., in the occasions requiring high temperature and high chemical stability, carbon fiber composite materials have advantages. High Quality Composite Tube - factory high strength 3K hollow round Carbon Fiber Tube 1000mm – Feimoshi , The product will supply to all over the world, such as: Costa Rica, Croatia, Brisbane, Winding types are: circumferential winding, vertical winding, spiral winding. Carbon fiber tubes are generally helically wound. In the whole process of winding, whether the tension between the small elephant, each carbon fiber or each layer of carbon fiber is uniform will immediately endanger the quality of the carbon fiber tube. In the process of increasing tension, the best tension is usually not fixed. Most of them are determined by improving the compressive strength of the raw material, the viscosity of the adhesive and the heating level of the core mold by means of the core mold structure.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.