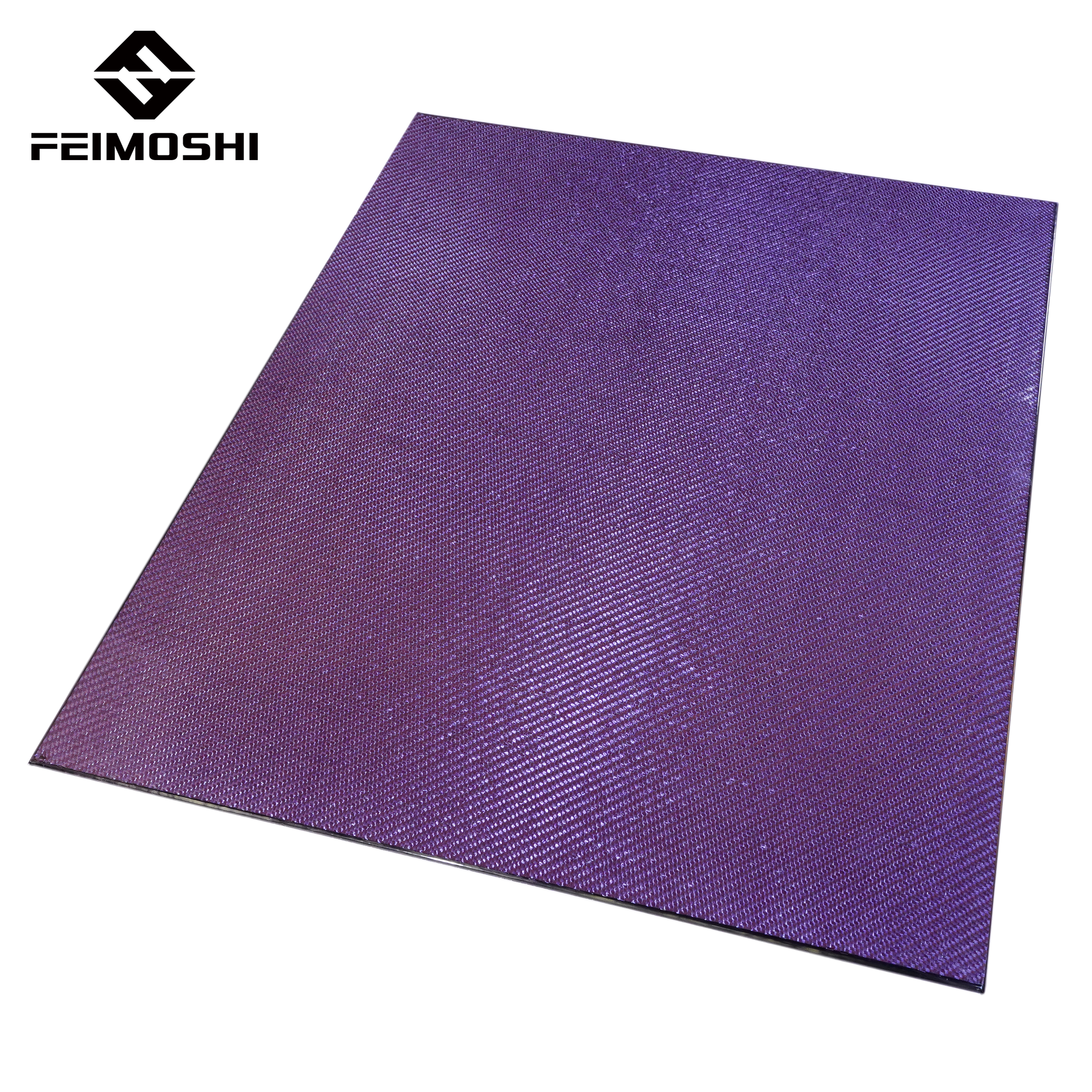

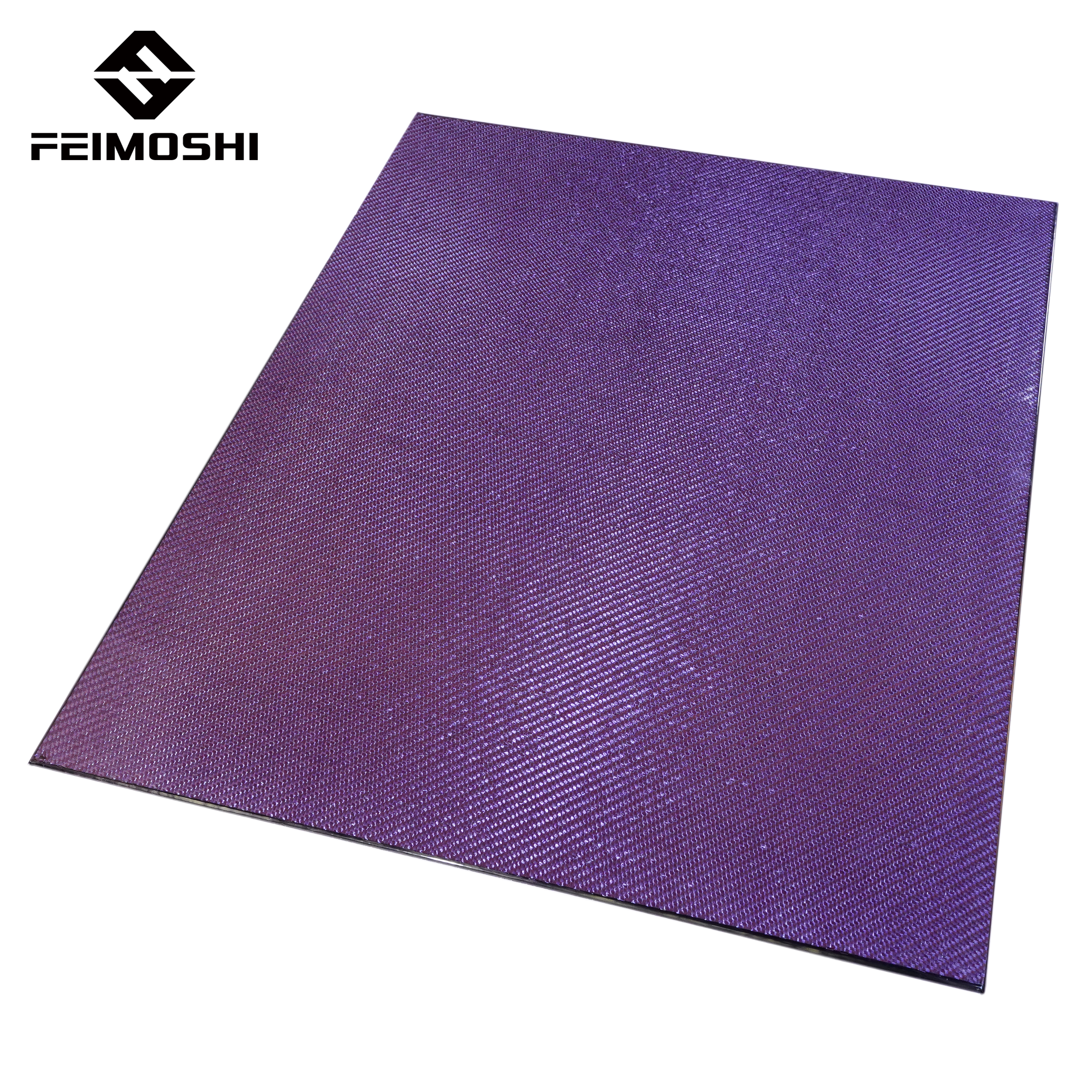

High reputation Thick Carbon Fiber Sheets – Purple 3K twill matte carbon fiber sheets for drone – Feimoshi

High reputation Thick Carbon Fiber Sheets – Purple 3K twill matte carbon fiber sheets for drone – Feimoshi Detail:

The carbon fiber board produced by our company has a 2×2 twill weave pattern, which is one of the most common weave patterns in many markets. The finished surface of the board has a classic 2×2 twill, 3K woven carbon fiber appearance, almost no pinholes, and high gloss.

The composite panels made of our high-strength vacuum autoclave are made of 100% carbon fiber and reinforced by a nearly transparent epoxy resin matrix. All composite material stacks are laid by hand to ensure maximum homogenization of the fiber arrangement. The stack is then vacuum infused and cured under a pressure greater than 28 inches of mercury. The tool is then raised to the optimum temperature to produce a nearly perfect composite board with advanced mechanical properties and A-level surface finish.

Laminated structure

To ensure the maximum structural integrity and flatness of all our panels, we produce “balanced” laminates for all panel thicknesses and dimensions. This means that the fiber type, weight, and weave pattern are symmetrical in all layers of the composite stack.

Plates of 1.4 mm/1/16 inch or thicker are quasi-isotropic laminates, made of non-woven, non-crimped carbon fiber layers, with orientations of 0º/90º/+45º/–45º. The orientation of the quasi-isotropic ply leads to the most uniform strength distribution and enhances torsional stiffness and diagonal stiffness.

Cross-stacking will produce boards with higher structural integrity, which may be required for many applications. The laminate stacking and laminate direction can be adjusted for specific applications; for example, if you need more board strength in a specific direction, but want to avoid adding extra laminate weight.

A detailed list of laminates and fabric stacks can be requested for each of our boards. Please specify the board model when inquiring.

Epoxy resin: All carbon fiber boards are made of high-performance epoxy resin, which has excellent mechanical functions, transparency and higher UV stability. An elevated post-curing temperature is applied to increase the mechanical strength of the board, which results in a higher Tg and enhances the interlaminar shear strength.

Product detail pictures:

Related Product Guide:

In the aerospace industry, carbon fiber sheets are used to make aircraft components such as fuselage panels, control surfaces and wingtips. The resulting components are lightweight, yet robust. Carbon fiber is widely adopted by the aerospace industry due to its superior strength-to-weight ratio. Because carbon fiber has such a beautiful appearance, it is also ideal for aircraft interiors. High reputation Thick Carbon Fiber Sheets – Purple 3K twill matte carbon fiber sheets for drone – Feimoshi , The product will supply to all over the world, such as: Johor, Ecuador, Lithuania, When cutting carbon fiber board, there are some tips to refer to. When cutting, you can mark it with a tool, and then widen the mark a little bit, so that you can leave enough space to sand the carbon fiber board a little, this way can avoid chips and debris, and make the edge of the carbon fiber board smoother, to further protect your own safety. After finishing the cut, there are also steps that can be taken to give a final polish to the cut edges. Buy some sanding blocks to sand the edges, or use sandpaper to smooth the edges.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.