The molding methods of carbon fiber products mainly include two ways: First, the molding process, the molding is to place the carbon fiber material between the upper and lower molds, under the action of the pressure and temperature of the hydraulic press, the material fills the mold cavity and removes the residual Air, after a period of high temperature and high pressure, solidifies the resin in the carbon fiber material, and a carbon fiber product can be obtained after demolding. This process greatly reduces the production cost, and has high production efficiency, and is suitable for forming carbon fiber products with complex structures. Second, the autoclave forming process, the autoclave is a special container that can withstand and adjust the stability and pressure within a certain range. The carbon fiber prepreg is laid on the surface of the mold coated with mold release agent, and then covered with mold release cloth, suction felt, isolation film, and air felt in turn, sealed in a vacuum bag, and heated and cured in an autoclave. Before, it needs to be vacuumed to check the tightness, and then put into an autoclave for curing and molding under the action of high temperature and high pressure. This process is suitable for load-bearing structural parts that require high mechanical properties. Structural Carbon Fiber, Carbon Fiber Bracket, Octagonal Composite Tube, Carbon fiber board features; A. High tensile strength, good corrosion resistance, shock resistance and impact resistance.Carbon fiber board has excellent physical and mechanical properties, the tensile strength is more than 10-15 times that of ordinary steel, the elastic modulus is better than that of steel, and it has excellent creep resistance, corrosion resistance and shock resistance. It is very suitable for reinforcement and repair of reinforced concrete.B, light weight, good flexibility. Carbon fiber board has higher strength than steel, and its quality is only 1/5 of steel. It has higher toughness, can be coiled, and can be supplied in larger lengths without overlapping. C. The construction is convenient and the construction quality is easy to guarantee.There is no wet operation, no need for large-scale construction equipment, and no need for on-site fixed facilities. The length of the carbon fiber board can be arbitrarily cut, the construction is simple, and the construction period is short. The material does not need to be pre-processed, the process is convenient, and the plates are allowed to cross.D. Good durability and corrosion resistance.Resistant to acid, alkali, salt and atmospheric corrosion without regular maintenance. And it has a protective effect on the internal concrete structure, and can achieve the purpose of double reinforcement and repair.

OEM/ODM China Composite Frame - 3K twill matte 200g prepreg carbon fiber cloth – Feimoshi Detail:

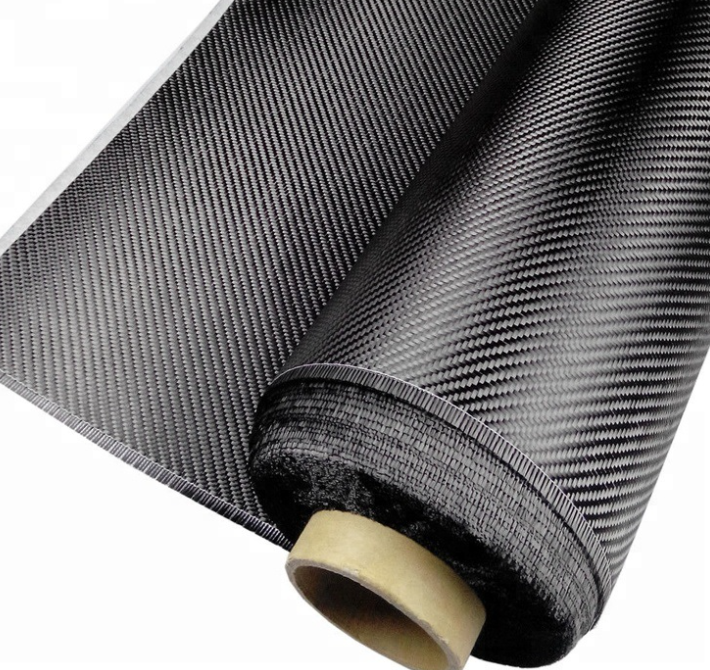

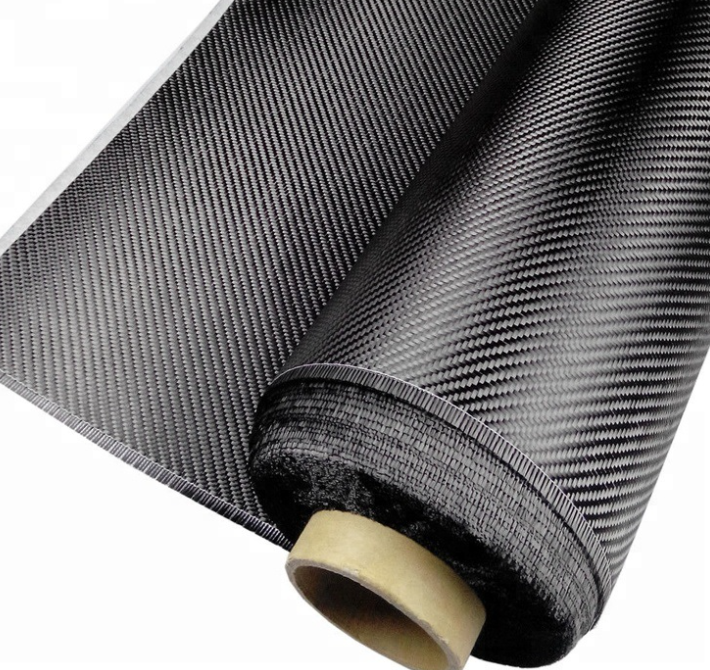

Carbon fiber cloth is woven from carbon fiber unidirectional, plain or twill weave.

The carbon fiber we use has high strength-to-weight ratio and stiffness-to-weight ratio.

Carbon fiber has thermal and electrical conductivity, and has excellent fatigue resistance.

Because of these high-quality characteristics, carbon fiber products are widely used in drones, military, medical industry and industry.

If properly designed, carbon fiber fabric composites can achieve the strength and rigidity of metals while significantly reducing weight.

Carbon fiber fabrics are compatible with various resin systems, including epoxy, polyester and vinyl ester resins.

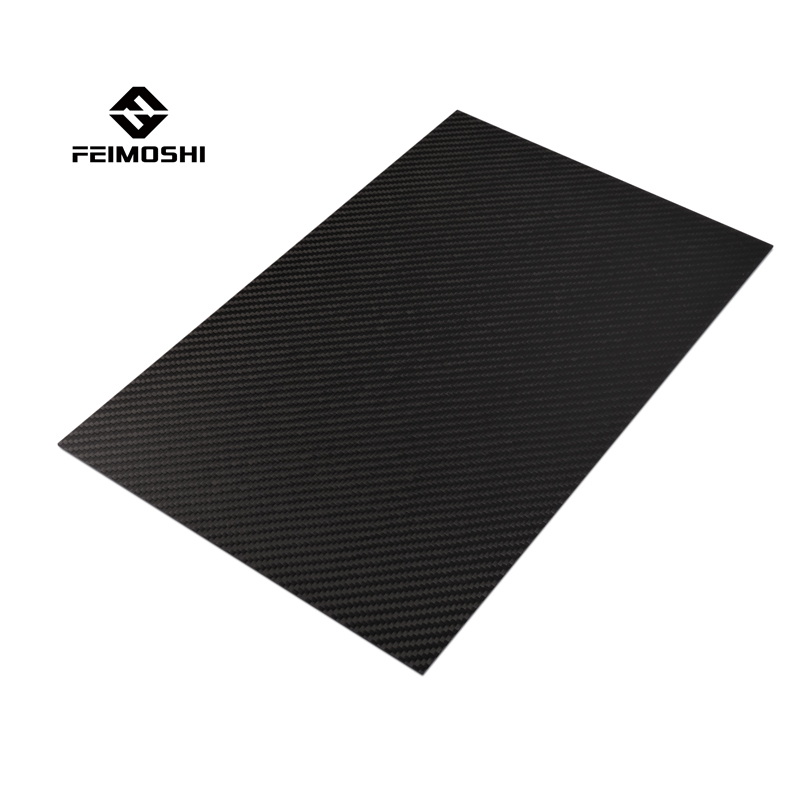

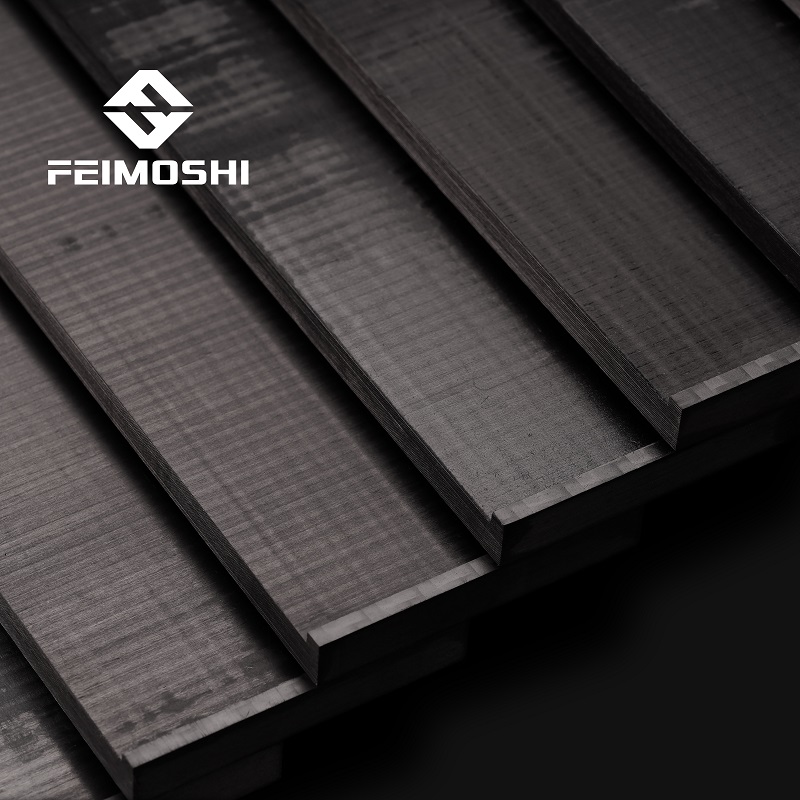

Our company produces various thicknesses of carbon fiber boards and carbon fiber tubes through carbon fiber cloth, and customizes various special-shaped carbon fiber accessories for customers.

Our design team can also help customers to match between accessories and accessories.

These services have brought more respectable, faster and more competitive products to our customers.

Product detail pictures:

Related Product Guide:

At this stage, many product parts are made of carbon fiber. Most parts are not standard plate and tube products. In the application environment, there are some inclination and shape regulations. Carbon fiber composite materials have good ductility, and epoxy resin can complete various intricate shapes in the flow of the mold. At this stage, the customized industry has a very large demand for such special-shaped parts. Some customers do not understand the basic knowledge of the production and application of carbon fiber special-shaped parts. OEM/ODM China Composite Frame - 3K twill matte 200g prepreg carbon fiber cloth – Feimoshi , The product will supply to all over the world, such as: Eindhoven, panama, Las Vegas, The surface of the wound carbon fiber prepreg must be coated with a layer of OPP, and then the wound carbon fiber tube is sent to a high-temperature curing furnace to dry and form, and finally the mold is released, and the unstable parts on both sides are cut off to carry out production and processing solutions.