PriceList for Carbon Fiber Chamfer - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi

PriceList for Carbon Fiber Chamfer - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi Detail:

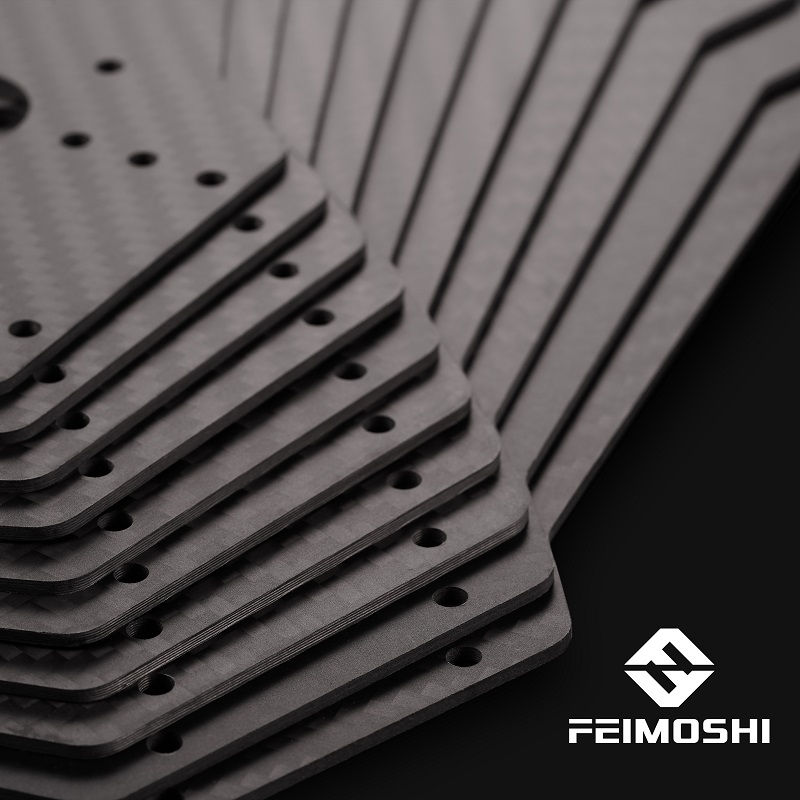

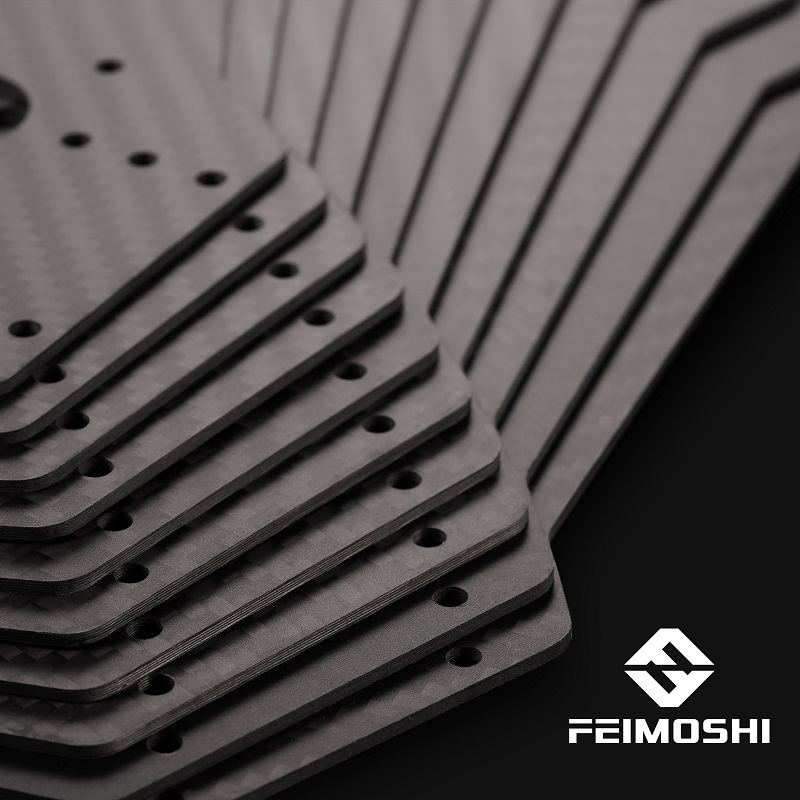

3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels

Carbon fiber plates are made from high-quality carbon fiber material, our carbon fiber sheets panels are durable, high quality, and affordable.

1. All our carbon fiber sheets are made with 100% real carbon fiber prepreg cloth. Varieties of carbon fiber sheets can be offered to meet different requirements.

2. Each sheet is hand finished and inspected. Special materials and processes ensure the flawless gloss on both sides.

3. Different thicknesses and sizes for choosing :

Size :400×500 ;500×500; 500x600mm thickness :0.3-20mm

FAQ

1) Do you make the T300/T700 carbon fiber plate?

Yes, our normal plate is Toray T300 full carbon fiber plate.

2) T700 is stronger than T300?

Normally, T300 plate is strong enough for the FPV drone.

Also some customers perfers the T700 plate. It is up to your choice.

3) Could we do the CNC cutting service?

Yes, CNC cutting, chamfer and countersunk are all ok.

4) How many days for the production time?

About 7-15 working days based on the drawings’ comprehensive.

5) Sample for testing is avaliable?

Of course, you could make the bulk order. And we will make the free sample for your testing.

Product detail pictures:

Related Product Guide:

At present, the carbon fiber industry is in a period of explosive growth, and the growth rate of the carbon fiber demand market will remain at around 17% in the future. PriceList for Carbon Fiber Chamfer - 3K Twill Woven Matte Cnc Cutting Carbon Fiber Panels – Feimoshi , The product will supply to all over the world, such as: Mexico, Botswana, Sri Lanka, With the improvement of the production process, carbon fiber board will popularize or replace many metal structural materials, providing the possibility for the lightness and convenience of products.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!