PriceList for Carbon Fiber Tube Accessories - Octagon Carbon Fiber Tube for Multicopter – Feimoshi

PriceList for Carbon Fiber Tube Accessories - Octagon Carbon Fiber Tube for Multicopter – Feimoshi Detail:

20x30x500mm Octagon Carbon Fiber Tube for Multicopter

Product Description

Carbon fiber roll wrapped tubes are ideal for all kinds of construction projects that require a light weight high performance sporting tube that can deal with forces from any direction.

We produced our unique Octagon carbon fiber tube for the drone. It makes the frame more stable and professional. Light weight and high strength is the major advantage for the copter. Thickness could be 1.0mm and 1.5mm in stock. We do 20X30X500mm, 20X30X600mm and 20X30X1000mm size in stock. Also various length is also ok for us.

Surface Finish: Glossy and Matte

Application: Aviation, models, vehicle modification and metal machine parts processing.

The main size and specifications: Fiber Specifications: 1K, 3K

Weaving Style: Plain. Twill

Fiber Type: Carbon fiber+carbon fiber, Carbon fiber+ glass fiber, Carbon fiber+aramid fiber

Thickness: Specific thickness can be met according to customer needs)

Specification in common use

|

23mm*25mm*1000mm |

20mm*22mm*1000mm |

|

19.5mm*22mm*1000mm |

18mm*20mm*1000mm |

|

18mm*16mm*1000mm |

14mm*16mm*1000mm |

|

10mm*12mm*1000mm |

8mm*10mm*1000mm |

|

6mm*8mm*1000mm |

can custom as per customer’s requires |

FAQ

1. Sample&Small Order?

Welcome to sample order to test and checking quality. Mixed samples are acceptable.

2. Lead Time

According to order volume answer production time. Never cheat customers!

3 . MOQ

Accpet small order&Servicer will depending on details situation provide some advices.

4. Goods Shipping

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive.

5. Visit Company

No problem for us, also we will provide technical support! Feedback Positive

Customization Process

1. Please contact freely and provide us with your drawings and specifications ;

2. We will quote for you within 1-3 days;

3. Orders need to pay the total purchase price of more than 30 percent down payment;

4. Confirm the sample;

5. Batch manufacturing;

6. Inform the customer to inspection the package;

7. Customers pay the balance payment;

8. Make a delivery.

For all parts, if you have any question, please feel free to contact us.

Looking for ideal 20x30x500mm Octagon Carbon Fiber Tube Manufacturer & supplier?

We have a wide selection at great prices to help you get creative. All the 3k Octagon Carbon Fiber Tubes are quality guaranteed. We are China Origin Factory of Carbon Fiber Tube for Multicopter. If you have any question, please feel free to contact us.

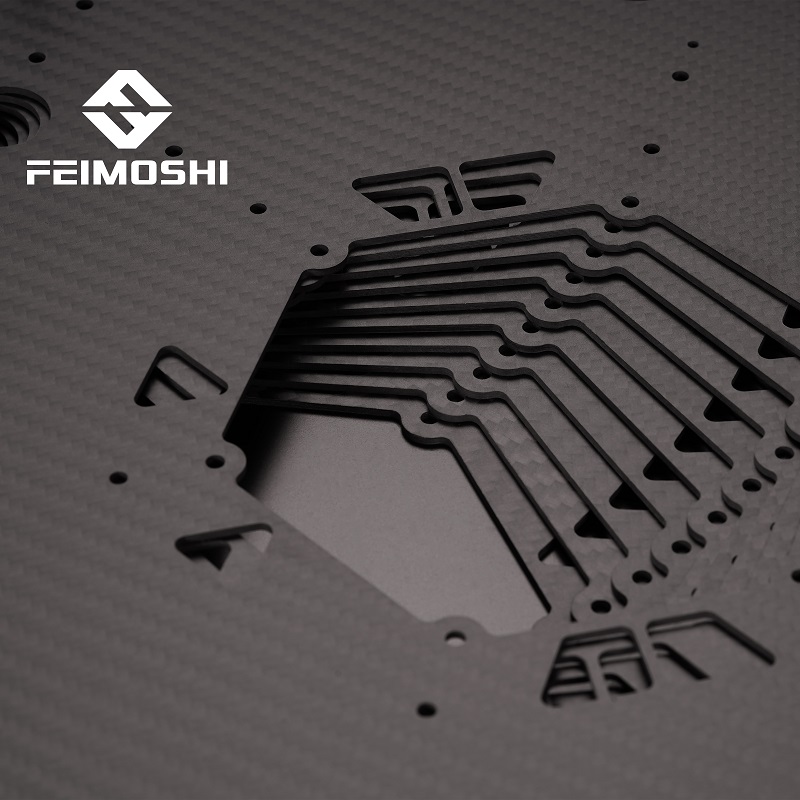

Product detail pictures:

Related Product Guide:

For special-shaped parts with complex shapes, if you want to use carbon fiber to complete it, you need to design 3D engineering drawings in the early stage, and make unique production molds according to the design drawings. Only after the mold is manufactured, can a series of processing processes be carried out, such as carbon fiber pre-soaking and laying, drying and forming, and finally the finished carbon fiber special-shaped parts can be produced. In the early stage of high-precision special-shaped parts, a large number of estimates and tests must be carried out, and the best scheme design and production methods must be sorted out to produce composite standard carbon fiber special-shaped parts products. During this period, all stages such as design plan, raw material selection, mold quality, construction quality control, etc. must be strictly followed. Neglect at all stages will jeopardize the final quality of the product. PriceList for Carbon Fiber Tube Accessories - Octagon Carbon Fiber Tube for Multicopter – Feimoshi , The product will supply to all over the world, such as: Greek, Sheffield, Milan, Carbon fiber tube, also known as carbon fiber tube, also known as carbon tube, carbon fiber tube, is made of carbon fiber composite material pre-impregnated with styrene-based polyester resin and then heated and cured by pultrusion (twisting).Carbon fiber tubes have the advantages of high strength, long life, corrosion resistance, light weight and low density, and are widely used in kites, aircraft models, lamp brackets, PC equipment shafts, etching machines, medical equipment, sports equipment and other mechanical equipment. A series of excellent properties such as dimensional stability, electrical conductivity, thermal conductivity, small thermal expansion coefficient, self-lubrication, energy absorption and shock resistance. And has high specific modulus, fatigue resistance, creep resistance, high temperature resistance, corrosion resistance, wear resistance and so on. The advantage is that it has very good tensile strength (for example, calculated in units of 12,000 filaments, its tensile strength is kg/mm2—400).

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.