Trending Products Carbon Fiber Keyboard Case - Aramid kevlar full Carbon Fiber Phone Case holder For iPhone 13 – Feimoshi

Trending Products Carbon Fiber Keyboard Case - Aramid kevlar full Carbon Fiber Phone Case holder For iPhone 13 – Feimoshi Detail:

Aramid kevlar full Carbon Fiber Phone Case holder For iPhone 13

Description:

Recently, iPhone 13 were sold very well. And our company also launched a carbon fiber phone case to match this phone.

(including iPhone13 mini, iPhone13, iPhone13 Pro, iPhone13 Pro Max).

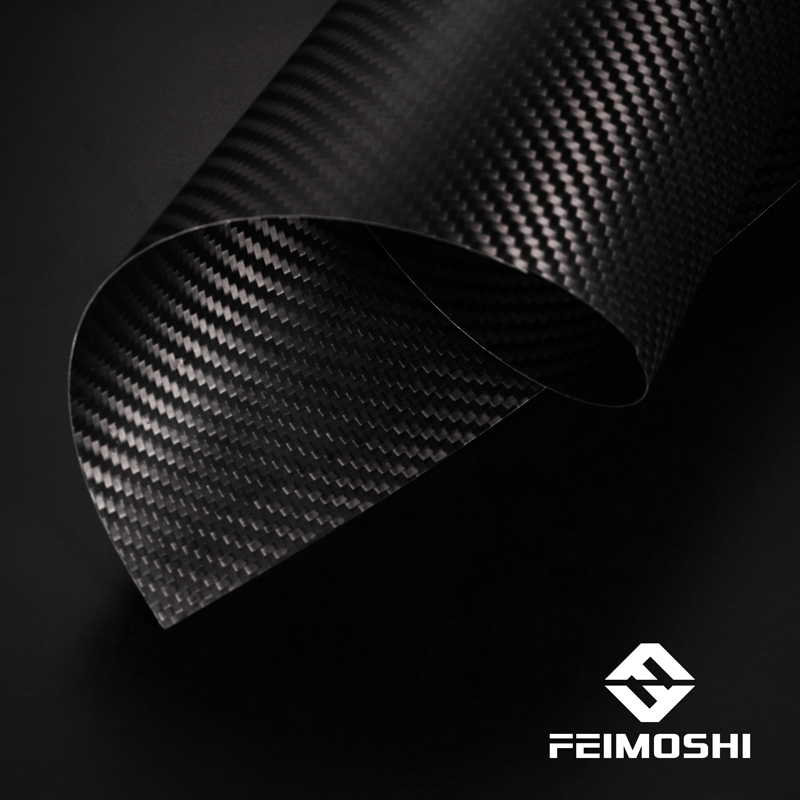

We use Kevlar to make it. it have light weight, good flexibility advantage.

At present, we only have black, red and brown color. if you need other color, we could customize it for you.

Our MOQ is 1pcs.

If any interested, welcome to send a inquiry to us.

Because Kevlar is a tough material, it may be slightly tougher to trim than our standard carbon veneers.

Can also be used for outdoor applications as we utilize a UV resistant resin that extends the life of the part and finish under sun exposure.

This carbon kevlar twill fabric combines the properties of 2 unique reinforcement yarns.

Carbon provides high levels of stiffness and strength, whereas aramid provides huge impact/abrasion/fracture resistance.

This distinct looking hybrid cloth is used in many high-performance, high-impact applications such as canoes, military ballistics and rally-car panelling.

Carbon/Kevlar twill cloth can be used in just the same way as standard carbon fibre.

When using only carbon/Kevlar reinforcement in a part you should expect to use several layers of this fabric in each part.

None-structural components like body panels and covers will typically require 3-6 layers of a carbon fibre cloth of this weight.

Although carbon and aramid fiber have similar characteristics, they also have some distinct differences:

A carbon fiber phone case is known for its tensile strength and compression that offers protection for your phone.

The downside to it, however, is that it gets brittle over time. An aramid phone case, on the other hand, is more flexible, which means that it will last longer.

Carbon fiber is naturally black, which is why most carbon phone cases are black because it’s tougher to dye in a different color.

Aramid fiber, on the other hand, light gold in color so it’s easier to dye in a wide variety of colors.

Carbon fiber is known to conduct electricity because of its natural characteristics.

This is why there’s a tendency that you might have some signal interruptions when you’re using a carbon fiber phone case.

On the other hand, you won’t have any signal problems with an aramid phone case.

In terms of strength and durability, both carbon fiber and aramid phone cases deliver to the highest standards.

In the end, it all boils down to flexibility.

Aramid phone cases are some of the thinnest and lightest cases that you’ll find in the market while carbon phone cases are a lot heavier because of their make.

Carbon gets the upper hand, however, when it comes to how it can protect your mobile phone.

So when choosing the best phone case, think about your lifestyle and what material would be most convenient for your needs.

Brand: FEIMOSHI

Name: Carbon fiber phone case

Color: red, black, brown

MOQ: 1 pcs

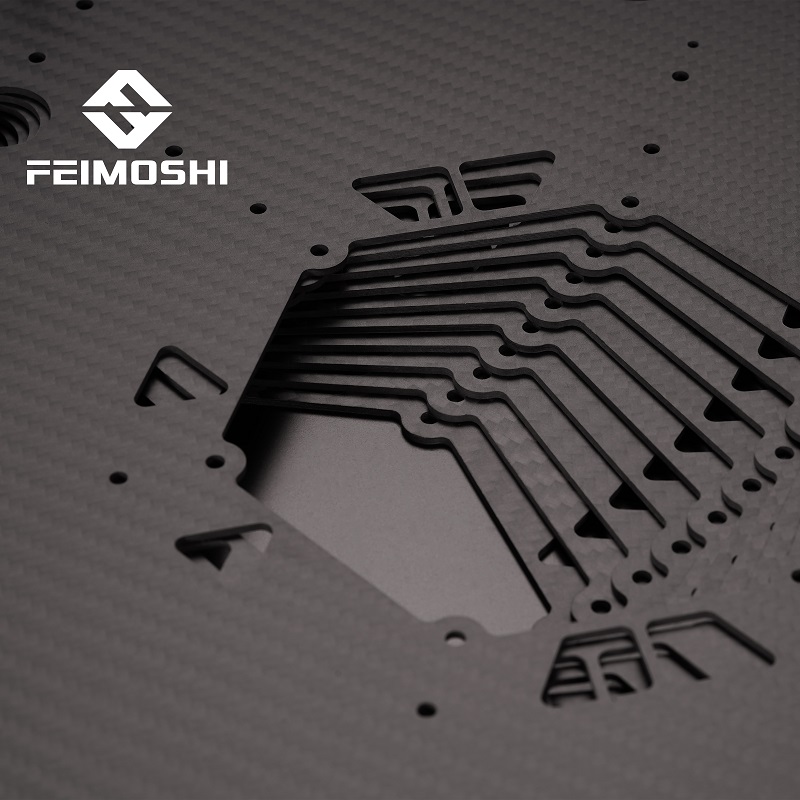

Product detail pictures:

Related Product Guide:

Carbon fiber is made of man-made fiber with high carbon content and does not melt during the whole process of heat treatment, and is made by thermal stable oxidation treatment, carbonization treatment and graphitization. In today's economic and social development, carbon fiber has long been widely used as a new material, ranging from aerospace industry equipment raw materials to small handbags and other fields. So why is carbon fiber so popular? What are its actual advantages? Trending Products Carbon Fiber Keyboard Case - Aramid kevlar full Carbon Fiber Phone Case holder For iPhone 13 – Feimoshi , The product will supply to all over the world, such as: azerbaijan, Mecca, Dominica, There are many kinds of carbon fiber tube production processes, such as winding molding, pultrusion molding, compression molding, roll molding, autoclave molding, air bag molding, etc., carbon fiber tubes with different needs often use different production processes. Common square tube molding and round tube rolling. The carbon fiber prepreg is used here, minus the impregnation process. Can improve production efficiency.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.